// OEM, ODM

HENGTAI GROUP - HENGTAI ZEYUAN

Cangzhou Hengtai Zeyuan Anti-corrosion Pipeline Co., Ltd, Hebei Hengtai Group, one of the subsidiaries of the Hengtai Group, Hengtai was founded in 1985, formerly known as Yanshan County Pipe Fittings Manufacturing Factory, after restructuring has developed into a set of pipeline technology research and development, pipeline equipment manufacturing, pipeline anticorrosion heat preservation, precision casting, construction and transportation machinery manufacturing, international trade as one of the large-scale industry and trade group companies.

The company has the main production and test equipment 480 sets, inspection and experimental equipment covers from raw materials, standard parts, semi-finished products to finished products of the various room temperature test, inspection program.

Hengtai was founded in

Total assets of group companies

Total number of employees

Production and test equipment

// PRODUCTS

CHOOSE OUR PRODUCTS

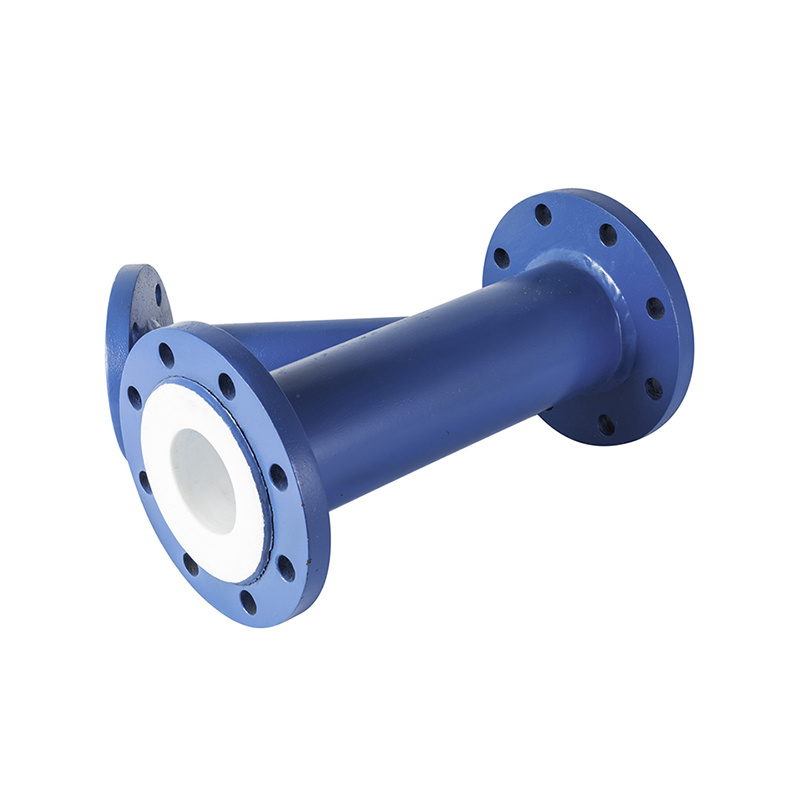

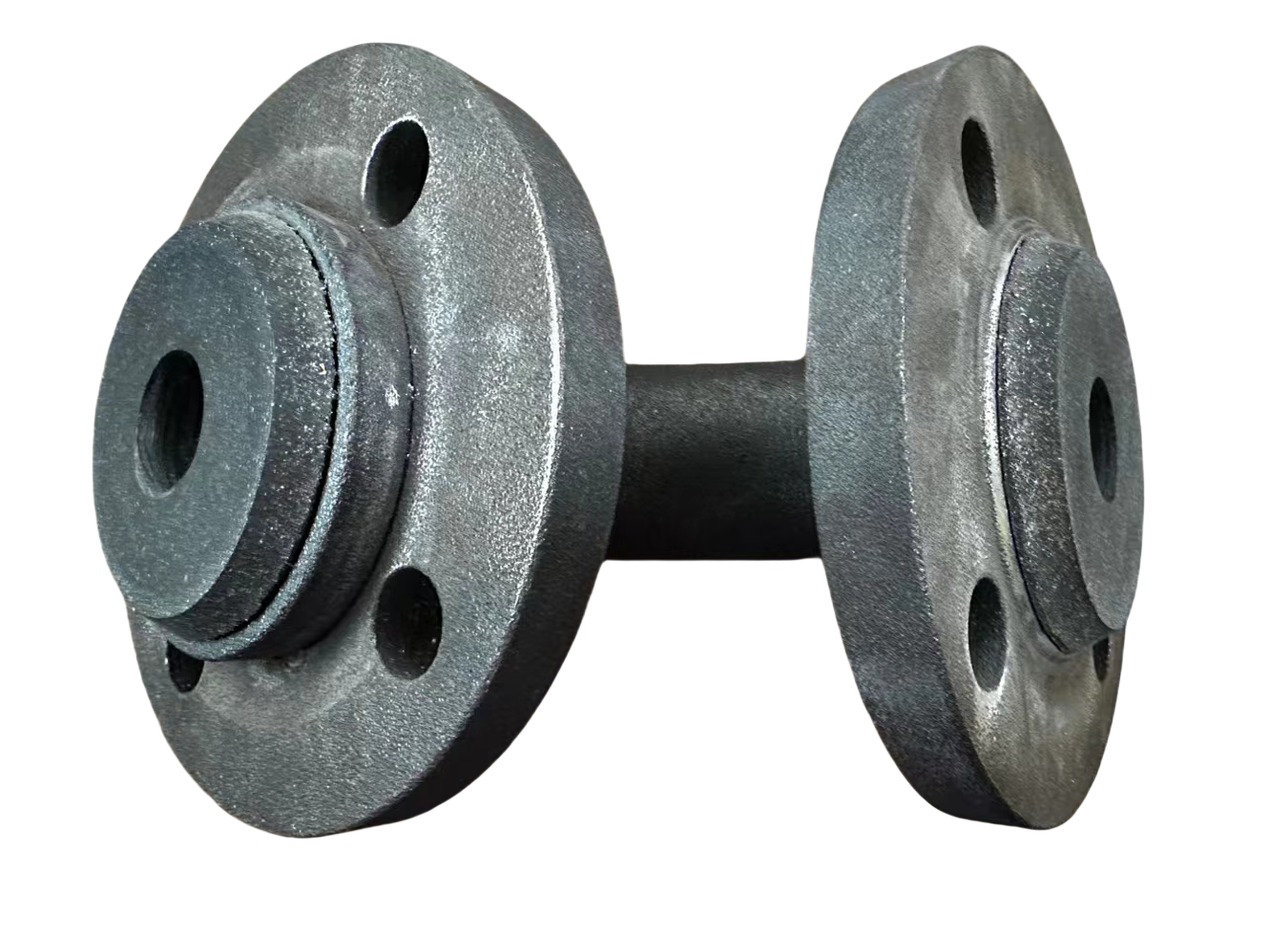

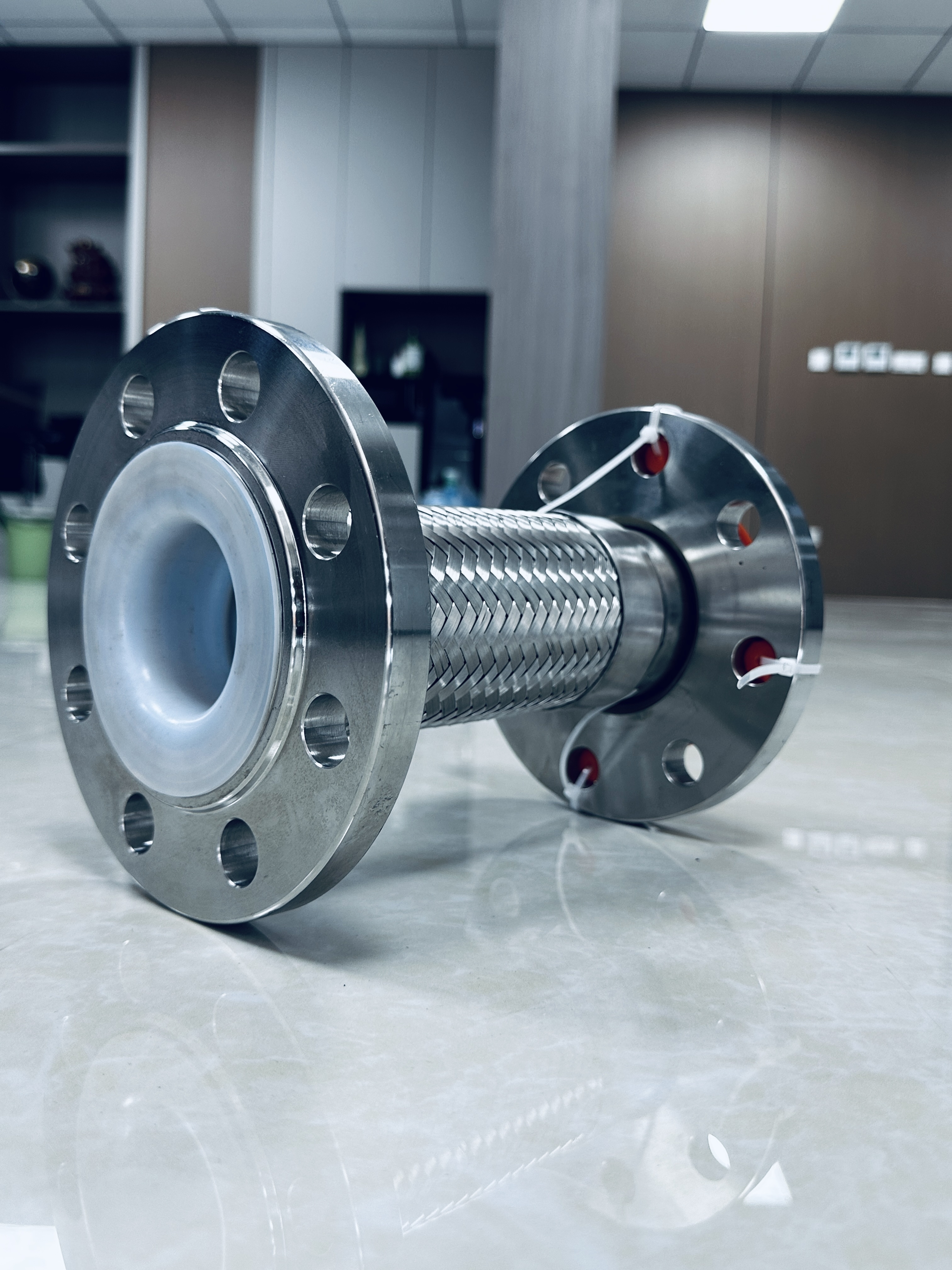

The main products are PTFE lined pipes, fittings, tanks, valves; plastic lined pipes, fittings, tanks, all kinds of shaped parts; rubber lined pipes, fittings; hot-dip plastic threading pipe and other anti-corrosion series products.

// WHY CHOOSE OUR COMPANY

SOME REASON FOR CHOOSEOUR COMPANY

Excellent product quality, its technical performance and indicators have reached the level at home and abroad.

// APPLICATION

Application Scenario

Products are widely used in petroleum, chemical, lithium, pharmaceutical, printing and dyeing, electrical, shipbuilding, metallurgy, military, semiconductor chemistry, electronic phosphoric acid and other modern anti-corrosion engineering fields.

// CONTACT US

Didn'T Find The Service You Want?

For inquiries about our products, please email to us and we will be in touch within 24 hours.

Monday to Friday 08:00-18:00

We Support Customization

Continue To Create Greater Value For Customers

// BLOG

News & Media

TRUSTED

We Trusted Our Customers

24/7 SUPPORT