Spiral Welded Steel Pipe (SSAW) Introduction

1. Product Definition

Spiral welded steel pipe is a type of welded steel pipe made from steel strip coils. The strip is helically coiled under normal temperature and welded using double-sided submerged arc welding (SAW). The weld seam is spiral-shaped, making the pipe suitable for various pressure transmission and structural applications.

2. Product Features

Wide Range of Diameters: Suitable for producing large-diameter pipes using relatively narrow strip steel.

High Strength and Pressure Resistance: The spiral seam distributes stress evenly.

Cost-Effective: More economical than longitudinal welded pipes for large diameters.

Good Welding Performance: Automatic double-sided SAW ensures stable welding quality.

Custom Lengths Available: Pipes can be cut to specific lengths as required.

3. Product Specifications

| Item | Specification Range |

|---|---|

| Nominal Diameter | DN200 - DN3000 (Φ219mm – Φ3000mm) |

| Wall Thickness | 5mm – 30mm (customizable) |

| Length | 6m – 18m (or customized) |

| Steel Grade | Q235B, Q345B, L245-L485 (API 5L), etc. |

| Welding Method | Double-sided Submerged Arc Welding (SAW) |

| Surface Treatment | Black, or anti-corrosion coatings (3PE, epoxy, etc.) |

4. Applicable Standards

| Standard Code | Standard Name |

|---|---|

| SY/T 5037 | Spiral Submerged Arc Welded Steel Pipe for Non-Pressure Fluids |

| GB/T 9711 | Steel Pipe for Pipeline Transportation Systems |

| API 5L | Line Pipe Specification (American Petroleum Institute) |

| EN 10219 | Cold Formed Structural Hollow Sections (EU Standard) |

| ISO 3183 | International Standard for Steel Line Pipes |

5. Main Applications

✅ Pipeline Transmission:

Long-distance transportation of oil and natural gas

Water supply and drainage systems

District heating pipelines

Industrial fluid transmission (chemicals, pharmaceuticals, wastewater, etc.)

✅ Structural Uses:

Steel structures in buildings and bridges

Piling pipes for ports, piers, foundations

Support pipes for tunnels and underground projects

✅ Other Uses:

Outer protection pipes for anti-corrosion and thermal insulation systems

Steel casing and sleeve pipes

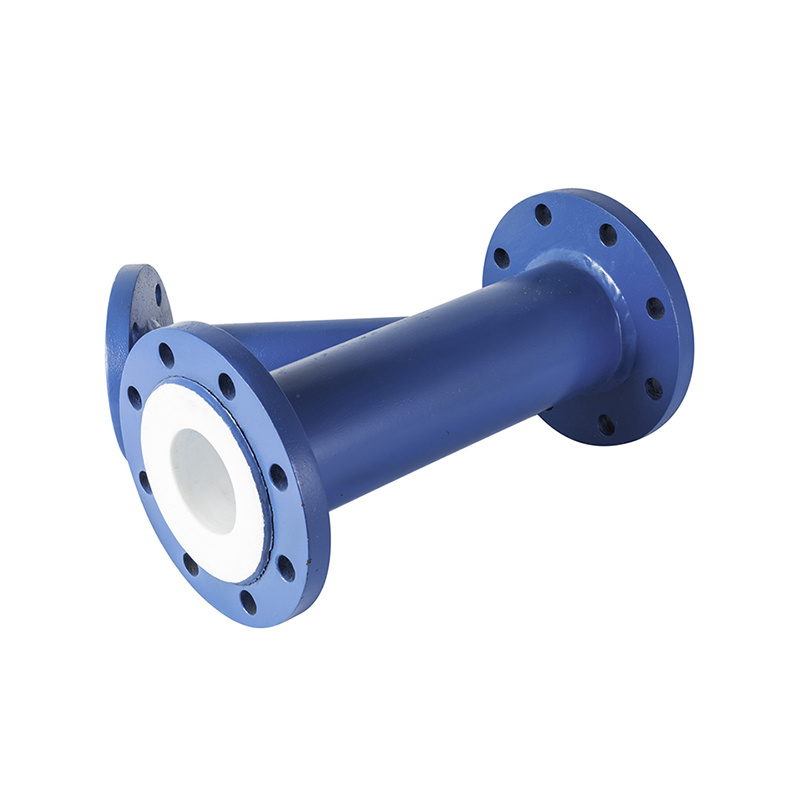

6. Common Anti-Corrosion Coatings

3PE (Three-layer Polyethylene Coating): Ideal for underground or submerged pipelines.

Epoxy Coal Tar Coating: Common in drainage, sewage, and municipal water supply systems.

FBE (Fusion Bonded Epoxy): Excellent adhesion and corrosion resistance.

Hot-dip Galvanizing: Suitable for environments with high oxidation requirements.

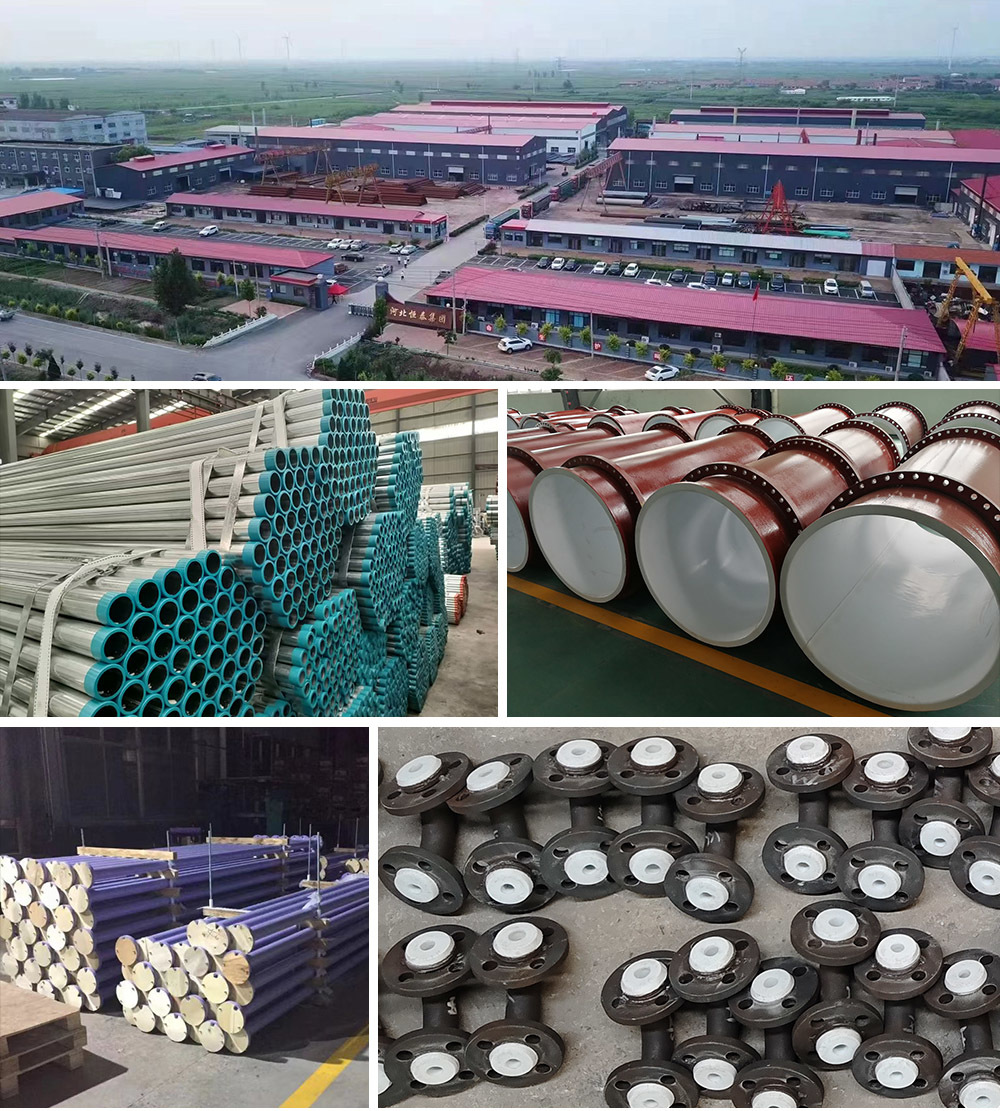

Factory Tour

Enterprise Qualification

Keywords

Spiral Welded Steel Pipe

Contact Us

Classification