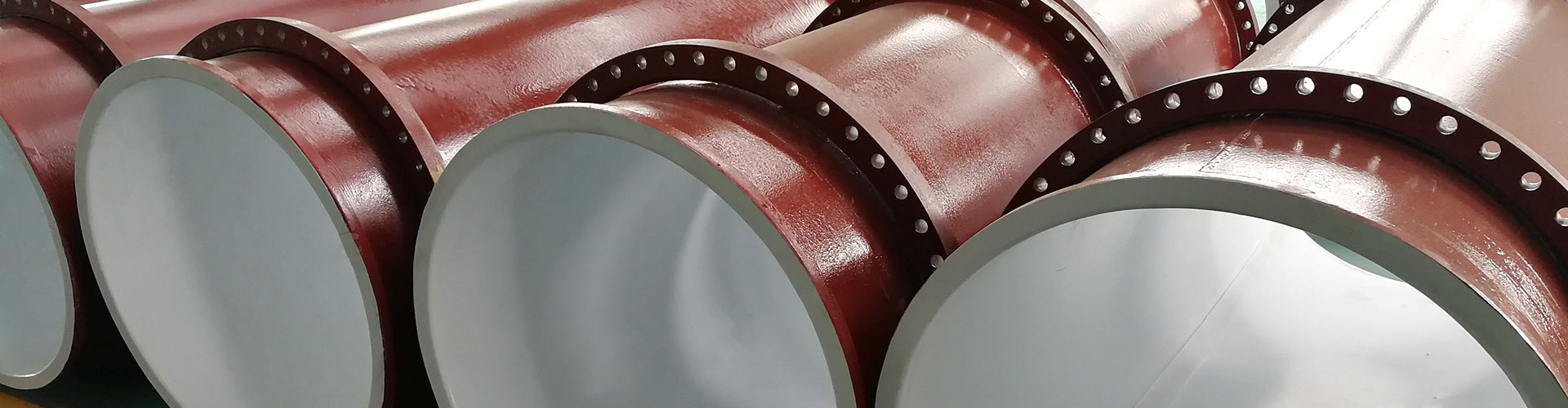

plastic-lined storage tank

An internally lined anti-corrosion storage tank is a type of tank that uses a layer of plastic lining on the interior to store various chemicals and corrosive liquids. The purpose of this design is to prevent direct contact between the stored media and the tank's interior surface, effectively preventing corrosion and extending the tank's service life.Key Features:Corrosion Resistance: The plastic lining materials, such as epoxy resin, polyethylene, or polypropylene, provide excellent resistance to corrosion, especially for storing acids, alkalis, salts, and other highly corrosive substances.Good Sealing: The plastic lining ensures a tight seal, preventing leaks and ensuring safety for both the environment and personnel.Temperature Resistance: Some plastic linings offer excellent performance at both high and low temperatures, making them suitable for extreme conditions.Wear Resistance and Aging Resistance: The material has high wear resistance and aging resistance, reducing wear and tear during long-term use.Cost-Effective and Environmentally Friendly: Compared to traditional metal anti-corrosion tanks, lined plastic tanks are lighter, more affordable, and help reduce secondary pollution from corrosion.Applications:Internally lined anti-corrosion storage tanks are widely used in industries such as chemical, pharmaceutical, petroleum, metallurgy, power, and food processing. They are primarily used to store acids, alkalis, salts, solvents, liquefied gases, and other chemicals. They are also suitable for environmental protection, wastewater treatment, and other applications.Installation and Maintenance:Installation Requirements: The tank foundation and support structure must be stable to avoid settlement or deformation, which could affect the tank's performance and longevity.Regular Inspections: Periodic checks should be made to assess the condition of the plastic lining for signs of aging, cracks, or detachment.Repair and Maintenance: If any damage or failure is found in the lining, it should be repaired promptly to maintain the tank's anti-corrosion properties.In conclusion, internally lined anti-corrosion storage tanks offer outstanding corrosion resistance, durability, and cost-effectiveness, making them indispensable in many industrial sectors.