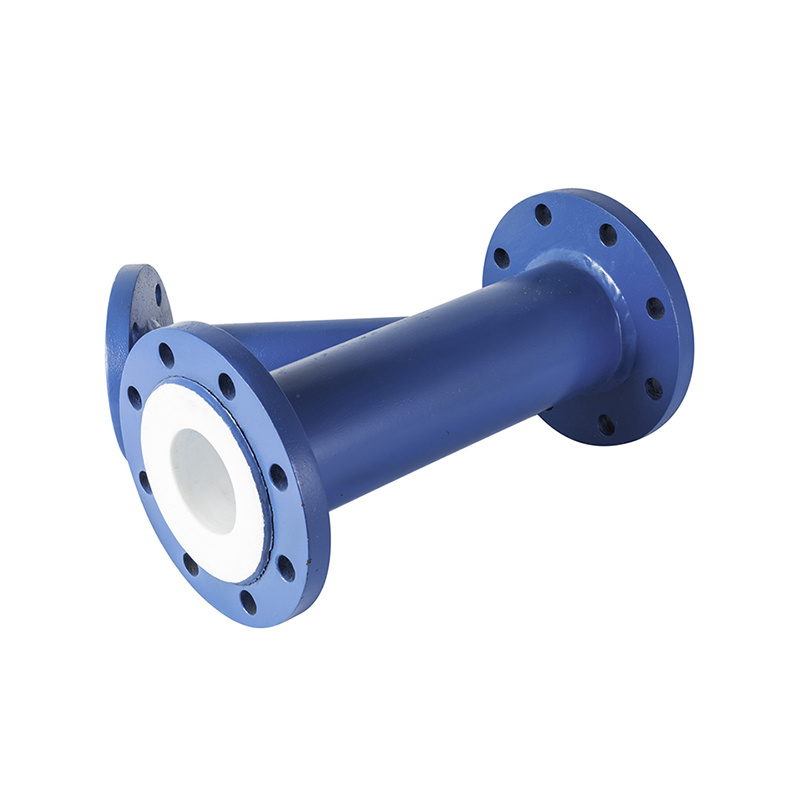

Lined fluoropolymer pipes are composite pipes made of ordinary carbon steel as the substrate, lined with polytetrafluoroethylene (PTFE). They combine the strength of metal pipes with the excellent properties of PTFE and are widely used in various fields. Here is a detailed introduction.

Structural Features

Layered Structure

Lined fluoropolymer pipes mainly consist of two layers: a metal outer wall and a PTFE inner lining. The metal outer wall is usually made of common steel pipes, such as seamless or welded steel pipes, which provide the overall strength and rigidity of the pipe to withstand internal and external pressures, support the weight of the pipe, and resist potential external impacts.

The PTFE inner lining is the key part of the lined fluoropolymer pipe, closely adhering to the inner surface of the metal outer wall, forming a continuous corrosion-resistant and wear-resistant layer. This layered structure allows the pipe to possess the mechanical properties of metal materials while also having the chemical stability and special physical properties of PTFE.

Connection Methods

Common connection methods include flange connections, butt welding, and socket connections. Flange connections facilitate the installation and disassembly of pipes, suitable for various pipe diameters, and ensure good sealing performance; butt welding offers high strength and sealing, commonly used in high-pressure and high-temperature piping systems; socket connections are relatively easy to operate, suitable for small diameter pipes, and are often used in situations with lower pressure requirements.

Performance Advantages

Excellent Chemical Stability

PTFE has extremely strong chemical inertness, capable of withstanding almost all corrosive media such as strong acids, strong bases, strong oxidizers, and organic solvents. In chemical production, lined fluoropolymer pipes can be used to transport various corrosive chemical raw materials, intermediates, and finished products, such as sulfuric acid, hydrochloric acid, nitric acid, and sodium hydroxide, effectively preventing corrosion and significantly extending the service life of the pipes.

Good High-Temperature and Low-Temperature Resistance

PTFE can maintain stable performance over a wide temperature range from -196℃ to 260℃. Therefore, lined fluoropolymer pipes can be used normally in high-temperature chemical reaction processes or low-temperature storage and transportation conditions without performance degradation, deformation, or damage due to temperature changes, giving them a unique advantage in many industries with special temperature requirements.

Extremely Low Friction Coefficient

PTFE has an extremely low surface friction coefficient, one of the lowest among known solid materials. This allows lined fluoropolymer pipes to have minimal resistance to fluid flow, reducing energy loss and improving transport efficiency. Additionally, the low friction coefficient effectively prevents solid particles in the medium from adhering to and accumulating on the inner surface of the pipe, reducing the risk of blockages.

Excellent Insulation Properties

PTFE has good electrical insulation properties, with low dielectric constant and dielectric loss, remaining stable over a wide frequency range. This makes lined fluoropolymer pipes suitable for certain special piping systems in industries such as electronics, electrical engineering, and chemicals, meeting both the functional requirements for transporting fluids and providing electrical insulation to prevent current leakage or short circuits.

Anti-Fouling and Easy to Clean

Due to its low friction coefficient and non-stick properties, the inner surface of lined fluoropolymer pipes is not easily contaminated by the medium. Even if a small amount of dirt adheres, it can be easily cleaned with simple rinsing or wiping. This is very important in industries such as food, beverages, and pharmaceuticals, where hygiene requirements are high, ensuring product quality and safety.

Production Processes

Winding Method

PTFE film or tape is evenly wound onto the inner surface of a pre-treated metal pipe at a certain angle and tension using winding equipment. During the winding process, appropriate adhesives can be added as needed to enhance the bonding strength between the PTFE layer and the metal pipe. Lined fluoropolymer pipes produced by the winding method have a uniform thickness of the PTFE inner lining, which can be flexibly adjusted according to actual needs, suitable for producing pipes of various diameters.

Molding Method

PTFE powder or prefabricated PTFE blanks are placed inside the metal pipe, and then pressed using a mold at a certain temperature and pressure, causing the PTFE material to tightly adhere to the inner surface of the metal pipe, forming the inner lining. Lined fluoropolymer pipes produced by the molding method have a high density of the PTFE inner lining and strong bonding with the metal pipe, but the production efficiency is relatively low, commonly used for producing pipes with high inner lining quality requirements and smaller diameters.

Spraying Method

Using a spray gun, PTFE powder or suspension is sprayed onto the inner surface of the metal pipe, curing at high or room temperature to form the inner lining. The spraying method allows for continuous production, high efficiency, and the ability to form a uniform inner lining on complex-shaped pipe surfaces, but it requires high standards for spraying equipment and processes, and the thickness of the inner lining is relatively thin, generally suitable for situations with no high requirements for lining thickness.

Application Fields

Chemical Industry

In chemical production, there is a significant demand for transporting corrosive media. Lined fluoropolymer pipes can be used to transport various corrosive fluids such as acids, bases, salt solutions, and organic compounds, ensuring the safe, stable, and efficient operation of chemical production processes.

Petrochemical Industry

Used for transporting crude oil, natural gas, various oil products, and petrochemical products, they can resist the corrosive components in oil products and meet the requirements for use under different temperature and pressure conditions.

Pharmaceutical Industry

The production of pharmaceuticals requires extremely high standards for the purity, chemical stability, and hygiene of pipelines. The chemical stability and easy cleaning properties of fluoropolymer-lined pipes make them an ideal choice for pharmaceutical companies to transport active pharmaceutical ingredients, intermediates, and finished products, effectively preventing contamination and ensuring drug quality.

Food and Beverage Industry

This industry requires pipelines to be non-toxic, odorless, corrosion-resistant, and easy to clean. The characteristics of fluoropolymer-lined pipes perfectly meet these requirements and can be used to transport various food ingredients and beverages, ensuring the hygiene, safety, and quality of food and beverages.

Electronics and Electrical Industry

In some electronic and electrical pipeline systems that require electrical insulation and corrosion resistance, fluoropolymer-lined pipes can be used to transport special electronic gases, chemical reagents, etc., while providing electrical insulation and pipeline protection functions, ensuring the normal operation of electronic and electrical equipment.

Water Treatment Industry

Used for transporting wastewater and reclaimed water containing various chemical agents, it can effectively resist the corrosion of corrosive substances in water on the pipes, extend the service life of the pipes, and reduce the maintenance costs of water treatment systems.

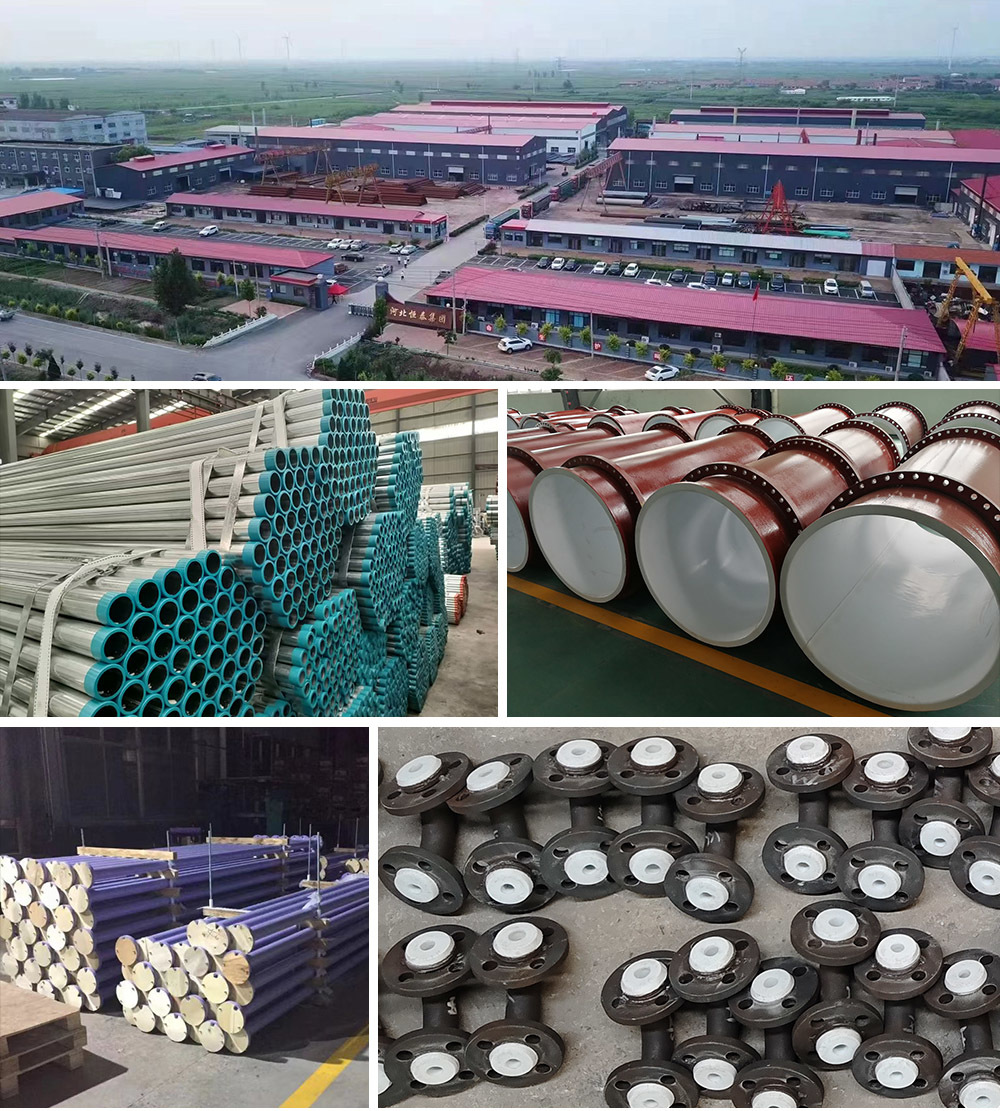

Factory Tour

Enterprise Qualification

Keywords

Steel Lined PTFE Pipeline for Chemical Applications

Contact Us

Classification