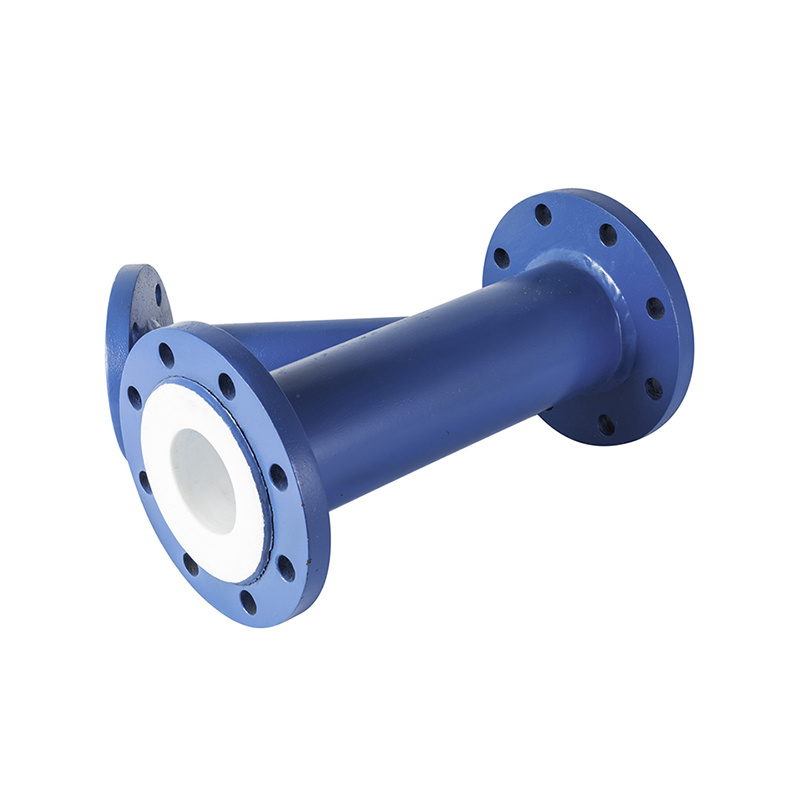

Rubber lined pipe fittings refer to metal fittings such as elbows, tees, crosses, reducers, and flanged pipes with an internal rubber lining. This lining enhances the corrosion resistance, wear resistance, and impact resistance of the fittings, making them ideal for harsh industrial environments.

Structure:

- Substrate (Base Material): Typically made of carbon steel, stainless steel, or cast iron, providing structural strength and pressure resistance.

- Lining Layer: A corrosion-resistant and wear-resistant rubber lining (such as natural rubber, butyl rubber, neoprene, EPDM, etc.) is firmly adhered to the inner wall of the metal fitting using high-temperature vulcanization or cold bonding processes.

Key Features:

- Excellent Corrosion Resistance: Suitable for strong acids, alkalis, salts, and other highly corrosive media.

- Superior Wear Resistance: Effective for transporting slurry, coal slurry, and other solid-containing fluids.

- Impact Resistance: The rubber lining absorbs impact energy, reducing damage from media flow.

- Good Sealing Performance: Prevents leakage and ensures a reliable seal under both vacuum and pressurized conditions.

- Extended Service Life: Longer lifespan compared to conventional metal fittings, reducing maintenance costs.

Applicable Industries:

- Chemical Industry: Handling strong acids, alkalis, salt solutions, and aggressive chemicals.

- Mining Industry: Transporting mineral slurry, tailings, and other high-abrasion materials.

- Power Industry: Used in coal-fired power plants for flue gas desulfurization (FGD) and ash handling systems.

- Metallurgical Industry: Suitable for pipelines carrying high-temperature corrosive gases or liquids.

- Environmental Protection: Applied in wastewater treatment, exhaust gas treatment, and sludge handling.

Common Types of Rubber Lined Pipe Fittings:

- Rubber Lined Elbow

- Rubber Lined Tee

- Rubber Lined Cross

- Rubber Lined Reducer

- Rubber Lined Flange Pipe

- Rubber Lined Spool Pipe

International Standards Compliance:

Our rubber lined pipe fittings are designed and manufactured in accordance with widely recognized global standards to ensure quality, durability, and performance:

- ASTM (American Society for Testing and Materials) – Ensures material quality and lining adhesion standards.

- ASME B16.5/B16.9 (American Society of Mechanical Engineers) – Covers dimensions, tolerances, and pressure ratings.

- DIN (Deutsches Institut für Normung) – Common European standard for industrial pipe fittings.

- ISO 9001 (International Organization for Standardization) – Guarantees quality management and consistency.

- GB/T (Chinese National Standards) – Ensures compliance with domestic and international regulations.

Customization Options:

We offer fully customizable rubber lined pipe fittings to meet specific industrial requirements:

- Material Selection: Carbon steel, stainless steel, or other alloys.

- Rubber Type: Natural rubber, butyl rubber, EPDM, neoprene, or custom formulations.

- Lining Thickness: Tailored to specific wear resistance and corrosion protection needs.

- Pipe Size & Dimensions: Available in standard and non-standard sizes per customer request.

- Flange Standards: ANSI, DIN, JIS, GB, or custom flanges as required.

- Special Coatings: Additional external coatings for enhanced environmental protection.

With our advanced manufacturing processes and strict quality control, we ensure that our rubber lined pipe fittings provide outstanding performance in even the most demanding applications.

Let me know if you'd like further refinements or a tailored version for specific markets! 😊

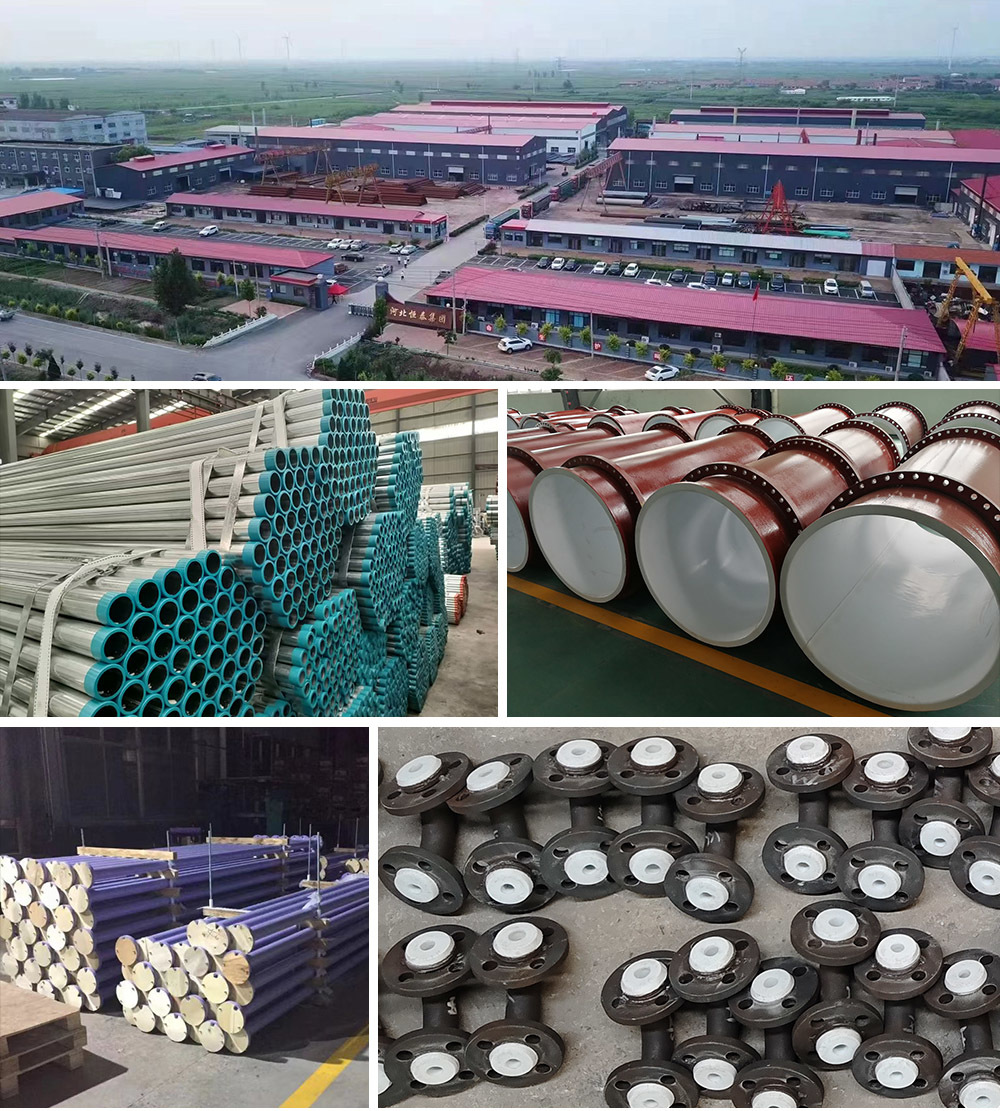

Factory Tour

Enterprise Qualification

Keywords

Rubber-lined wear-resistant and impact-resistant pipeline and fittings

Contact Us

Classification