1. Product Overview

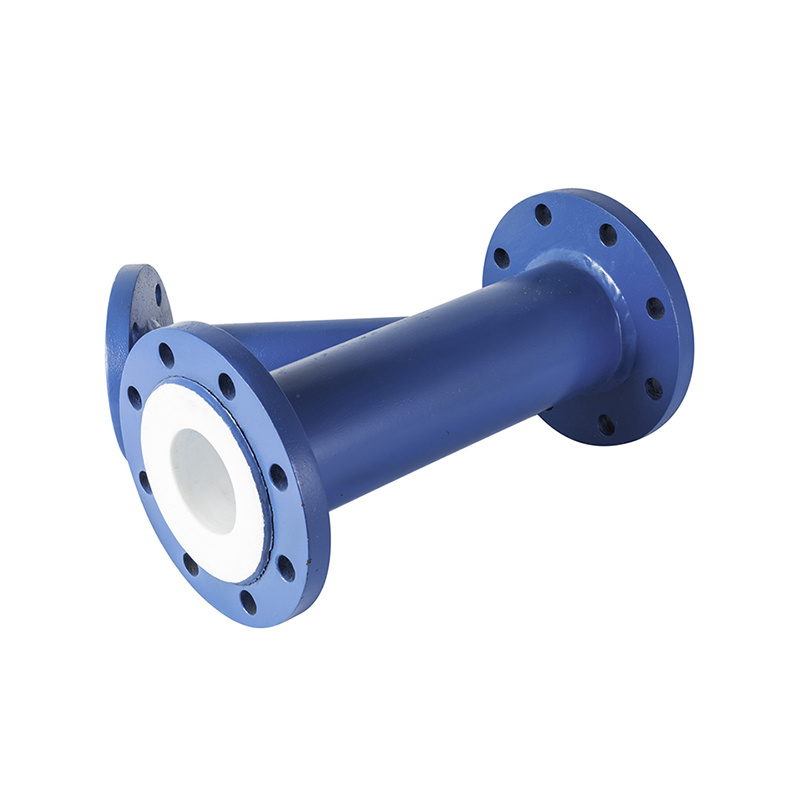

Custom lined ceramic pipelines are designed to provide superior resistance to wear, corrosion, and abrasion, making them ideal for industries that involve the transportation of highly abrasive or corrosive materials. These pipes have a strong metal base, typically made of carbon steel or stainless steel, and are internally lined with a layer of ceramic material, such as alumina (Al2O3) or zirconia (ZrO2), to offer enhanced durability and protection.

These pipelines are commonly used in industries such as mining, cement production, coal handling, power generation, chemical processing, and wastewater treatment. The ceramic lining improves the pipeline's lifespan and ensures minimal maintenance, reducing operational downtime. The pipelines can be customized in terms of size, material, and design to suit specific project requirements, including the use of flanged connections like loose sleeve flanges (活套法兰) and blind flanges (盲板法兰).

2. Main Features

- High Abrasion Resistance: The ceramic lining offers exceptional resistance to abrasive materials, preventing wear and prolonging the lifespan of the pipeline.

- Corrosion Resistance: Ceramic-lined pipelines can handle highly corrosive substances like acids, alkalis, salts, and other chemicals.

- Heat Resistance: Ceramic materials can withstand high temperatures, making them suitable for applications in hot environments (up to 1000°C, depending on the lining material).

- Improved Flow Efficiency: The smooth ceramic surface reduces friction, enabling better fluid flow and minimizing energy loss.

- Customizable Sizes and Design: Pipes can be tailored to specific dimensions, flange types, and lengths to meet customer needs.

- Long Service Life: Due to the hardness of ceramic materials, these pipelines have a longer lifespan compared to traditional metal pipes, reducing maintenance and replacement costs.

- Lightweight: The ceramic lining adds minimal weight to the pipeline, allowing for easier installation and handling.

3. Customization Options

| Nominal Diameter (DN) | Base Material | Lining Material | Pipe Shape | Flange Type | Connection Type | Wall Thickness (mm) | Applicable Pressure (MPa) | Applicable Temperature (°C) |

|---|---|---|---|---|---|---|---|---|

| 25-1200mm | Carbon Steel, Stainless Steel | Alumina (Al2O3), Zirconia (ZrO2) | Straight, Curved, Elbow | Loose Sleeve Flange, Blind Flange | Flanged, Welded, Threaded | 3-15mm | 1.0-2.5 | -40 ~ 1000 |

| 50-800mm | Carbon Steel | Alumina (Al2O3) | Straight, Curved | Loose Sleeve Flange, Blind Flange | Flanged Connection | 3-10mm | 1.0-2.5 | -40 ~ 600 |

| 50-600mm | Stainless Steel | Alumina (Al2O3), Zirconia (ZrO2) | Straight, Curved, T-Joint | Loose Sleeve Flange, Blind Flange | Flanged Connection | 3-12mm | 1.0-2.5 | -40 ~ 800 |

| 100-1000mm | Carbon Steel | Alumina (Al2O3) | Straight, Curved | Loose Sleeve Flange, Blind Flange | Flanged Connection | 5-15mm | 1.0-2.5 | -40 ~ 1000 |

4. Applications

- Mining Industry: Used for transporting abrasive materials such as coal, ores, and sand.

- Cement Industry: Ideal for conveying cement powder, clinker, and other abrasive substances.

- Power Generation: Applied in handling coal slurry, fly ash, and other materials in power plants.

- Chemical Industry: Suitable for handling corrosive chemicals, acids, and alkalis.

- Wastewater Treatment: Used for transporting slurry, sewage, and other high-abrasion materials.

- Material Handling: Ideal for applications where material flow needs to be smooth and free of blockages, including the transportation of granules, powders, and other solid particles.

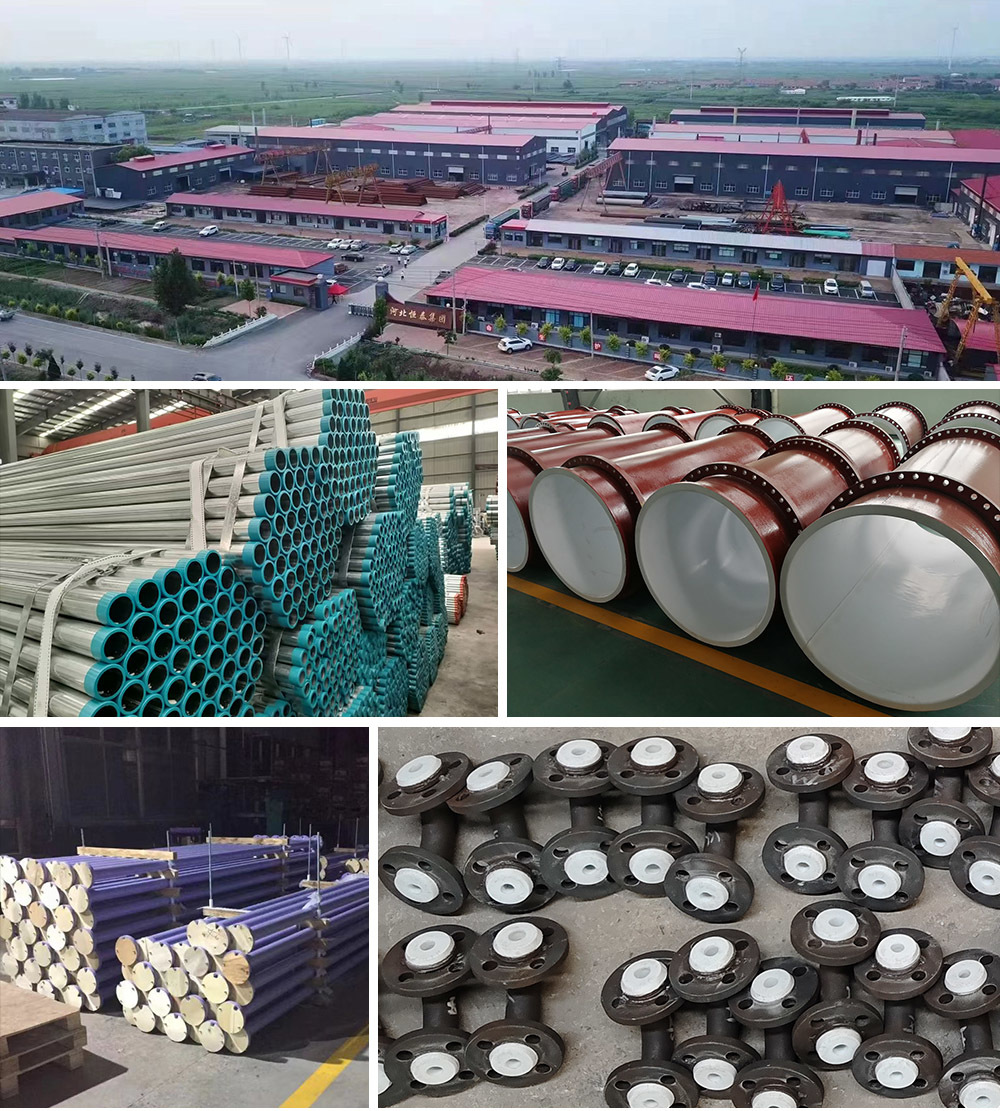

5. Manufacturer – Hebei Hengtai Zeyuan Anti-Corrosion Pipeline Co., Ltd.

Company Overview:

Hebei Hengtai Zeyuan Anti-Corrosion Pipeline Co., Ltd. is a recognized leader in the manufacturing of ceramic-lined pipelines. With years of experience and a commitment to high standards, we offer customized solutions to meet the specific needs of industries requiring durable, abrasion-resistant, and corrosion-resistant pipelines.

Advantages of Working with Us:

- Customization Flexibility: We provide tailored solutions in terms of size, material, and connection types, ensuring the best fit for your project requirements.

- High-Quality Materials: We use top-grade ceramic materials to ensure high resistance to abrasion and corrosion.

- Rigorous Quality Control: Our products undergo stringent testing and quality checks to meet industry standards and ensure reliability.

- Timely Delivery: We pride ourselves on our efficient production processes, ensuring that your order is delivered on time.

- Expert Support: Our team of engineers is available to provide technical guidance and assistance throughout the project.

Factory Tour

Enterprise Qualification

Keywords

Ceramic-lined wear-resistant and corrosion-resistant pipeline

Contact Us

Classification