Categories

Contact

E-mail :

mark@htzylinedpipes.com

WhatsApp:

+86-15632750373

Address:

Hebei Hengtai Group, 338 National Road North, Zhenggang Industrial Park, Yanshan County, Cangzhou City, Hebei Province

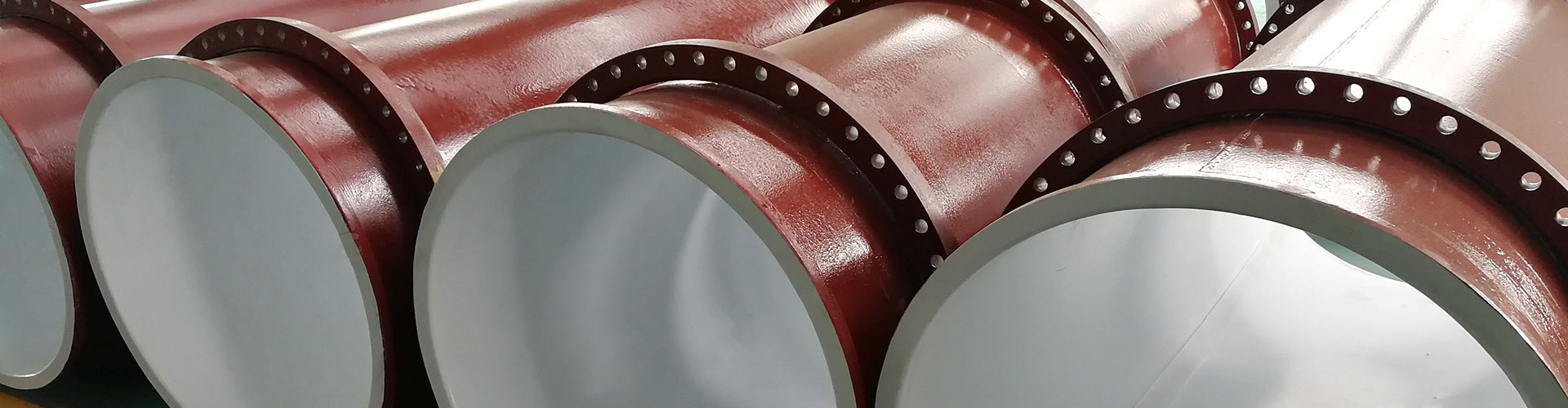

Coal Tar Epoxy Anti-corrosion Pipes

Epoxy coal tar enamel (ECT) anti-corrosion pipes

Epoxy coal tar enamel (ECT) anti-corrosion pipes are made by applying an epoxy coal tar enamel coating to the exterior of steel pipes, providing effective corrosion protection in harsh environments. This type of anti-corrosion pipe is widely used in industries such as oil and gas, water supply, sewage treatment, and petrochemicals, where pipes are exposed to aggressive conditions, including moisture, chemicals, and high pressure. The combination of the steel core and the protective coating makes ECT pipes ideal for long-lasting performance in aggressive environments.Key Features:Outstanding Corrosion Resistance: The epoxy coal tar enamel coating provides excellent protection against corrosion from water, soil, and chemical media, including salts, acids, and alkalis. The coating is resistant to aggressive corrosion, making it ideal for underground or submerged installations.High Durability: Epoxy coal tar enamel has exceptional resistance to mechanical wear, environmental factors, and aggressive chemicals. It enhances the life expectancy of the steel pipe, reducing the frequency of maintenance or replacement.Excellent Adhesion: The coal tar enamel coating bonds tightly to the steel surface, forming a protective layer that adheres well even under high mechanical stress and temperature variations. This strong adhesion prevents corrosion from occurring at any weak points.Thermal and Chemical Stability: Epoxy coal tar enamel offers excellent performance in a wide temperature range, typically from -40°C to 80°C, depending on the specific formulation. It also shows high chemical resistance to hydrocarbons, acidic solutions, and various chemicals commonly found in industrial pipelines.High Abrasion Resistance: The coal tar enamel coating forms a thick, durable layer that resists abrasion, ensuring that the pipe maintains its integrity even when exposed to rough handling or high-flow conditions. This feature is particularly useful in mining, oil, and gas transport.Water and Moisture Resistance: The coating's water and moisture resistance make it ideal for use in humid environments, ensuring that the steel pipe is protected from corrosion even when buried underground or submerged in water.Environmental and Safety Considerations: Epoxy coal tar enamel coatings are environmentally friendly and safe to use, with low toxicity and no significant harm to surrounding ecosystems when properly applied.Easy to Apply: The epoxy coal tar enamel coating can be applied using various methods, including spray, brush, or dip coating, allowing for flexibility in manufacturing and installation processes.Cost-Effective: This type of coating is more affordable compared to some other advanced coatings, offering a cost-effective solution for projects where long-term corrosion protection is required.Applications:Oil and Gas Industry: For transporting crude oil, natural gas, and other hydrocarbons, where protection from corrosion is critical.Water Supply and Sewage Systems: Used for pipes carrying drinking water, sewage, or wastewater, particularly in areas prone to corrosion.Marine Applications: Suitable for pipelines exposed to seawater or other corrosive marine environments.Chemical and Petrochemical Industries: For transporting chemicals and industrial liquids, including in environments where exposure to corrosive substances is common.Mining and Industrial Pipelines: For use in mining slurry pipelines and other industrial process pipes that need robust corrosion protection.Technical Specifications:Coating Type: Epoxy coal tar enamel (ECT)Thickness of Coating: Typically ranges from 0.3 mm to 1.5 mm, depending on pipe size and application.Temperature Resistance: Typically -40°C to 80°C, depending on the formulation.Pressure Rating: Varies depending on the application but can typically handle up to 16 MPa or higher.Adhesion Strength: ≥ 2.0 MPaAbrasion Resistance: Typically tested using the Taber abrasion test; the coating should show minimal wear under standard conditions.Benefits:Long-Term Protection: Offers excellent corrosion protection, which significantly extends the service life of the pipeline.Cost-Effective: A more affordable option compared to other specialized coatings, providing effective corrosion control at lower costs.Low Maintenance: The durable coating reduces the need for regular inspection, maintenance, and repair of pipelines.Adaptability: Suitable for a wide range of industries and environments, making it a versatile solution for diverse applications.Reliability: Proven to perform well under harsh conditions, making it a reliable choice for critical infrastructure systems.Epoxy coal tar enamel anti-corrosion pipes offer a robust solution for pipelines exposed to harsh environmental conditions. The combination of steel’s strength and the coating’s corrosion resistance ensures a long-lasting and low-maintenance piping system suitable for a variety of industrial applications.