Categories

Contact

E-mail :

mark@htzylinedpipes.com

WhatsApp:

+86-15632750373

Address:

Hebei Hengtai Group, 338 National Road North, Zhenggang Industrial Park, Yanshan County, Cangzhou City, Hebei Province

Insulated, spiral and galvanized steel pipes

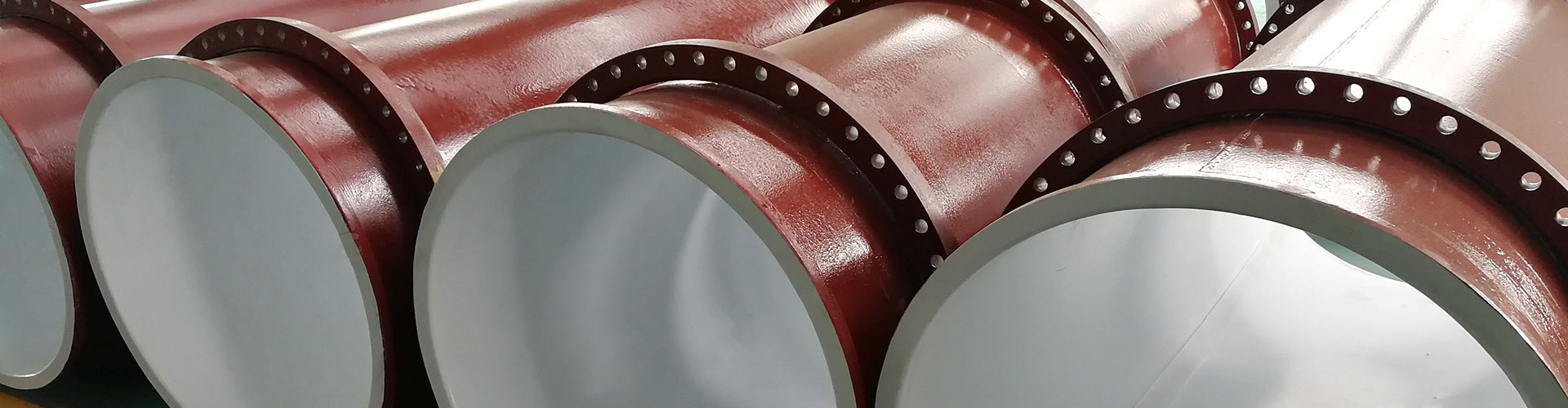

Product material: composed of high-density polyethylene outer pipe, polyurethane foam insulation layer, and inner working steel pipe.

Hot-dip Galvanized Steel Pipe📌 Product DescriptionHot-dip galvanized steel pipe is a steel pipe that has been coated with a layer of zinc through the process of hot-dip galvanization. This process involves immersing the steel pipe into a bath of molten zinc at approximately 450°C, forming a metallurgical bond between the zinc coating and the steel substrate. The resulting zinc layer provides excellent corrosion resistance and extends the service life of the pipe in a wide range of environments.Hot-dip galvanized pipes are available in both seamless and welded forms, and are widely used in applications where durability, corrosion resistance, and a clean, finished appearance are required.⭐ Key Features✅ Superior Corrosion ResistanceThe zinc coating acts as a sacrificial layer that protects the base steel from rust and corrosion, even when the coating is scratched.✅ Strong Mechanical PropertiesMade from high-quality carbon steel, these pipes offer good tensile strength and load-bearing capacity.✅ Durable Zinc CoatingThe hot-dip process results in a uniform, tightly bonded zinc layer that adheres strongly to the surface and offers long-lasting protection.✅ Cost-Effective LongevityWith minimal maintenance, hot-dip galvanized pipes offer a low life-cycle cost compared to painted or untreated steel pipes.✅ Attractive AppearanceThe silver-gray surface provides a clean, industrial aesthetic suitable for exposed use.📐 SpecificationsParameterDescriptionOuter Diameter1/2" – 12" (DN15 – DN300), or customizedWall Thickness1.5mm – 12mmLength5.8m, 6m, 12m, or customized as requiredSteel GradesQ195, Q235, Q345, S235, S275, ASTM A53/A500, BS EN 10255, etc.Zinc Coating200g/m² – 600g/m² (can be customized)Pipe EndsPlain, beveled, or threaded with plastic caps or couplingsSurface FinishHot-dip galvanized (shiny or matte), with or without oil coatingManufacturing TypesWelded (ERW), SeamlessTolerancesAccording to API, ASTM, or customer requirements📚 Standards CompliedStandardDescriptionASTM A53 / A123American Standard for galvanized steel pipesBS 1387British Standard for galvanized welded steel tubesEN 10240European standard for zinc coating of steel tubesISO 65International standard for galvanized steel tubingDIN 2444German standard for hot-dip galvanized steel pipes🏗️ Main ApplicationsConstruction & InfrastructureStructural supports, guardrails, scaffolding, greenhouse frames, roofing frameworksWater Supply & Drainage SystemsPotable water pipelines, sewage lines, irrigation pipesGas & Air TransmissionNatural gas distribution, compressed air systemsFire Protection SystemsSprinkler pipe networks in residential, commercial, and industrial buildingsFencing & Agricultural UseFencing posts, greenhouse poles, livestock sheltersCommunication & Utility StructuresElectrical conduit, telecom towers, solar mounting frames🛡️ Advantages Compared to Other PipesLonger lifespan (up to 50 years in dry environments)Self-healing protection at scratches (zinc oxidation protection)Suitable for both indoor and outdoor useNo painting required – maintenance-free in most applicationsExcellent for welding, cutting, and threading🎨 Surface Treatment OptionsHot-dip Galvanized (HDG): Immersed in molten zinc for full coverage protectionPre-galvanized (PG): Zinc coating applied to steel strip before formingClear/Anti-rust Oil Coating: Applied to prevent white rust during storagePassivation: Chromate treatment to enhance corrosion resistance and appearance

Spiral Welded Steel Pipe (SSAW) Introduction1. Product DefinitionSpiral welded steel pipe is a type of welded steel pipe made from steel strip coils. The strip is helically coiled under normal temperature and welded using double-sided submerged arc welding (SAW). The weld seam is spiral-shaped, making the pipe suitable for various pressure transmission and structural applications.2. Product FeaturesWide Range of Diameters: Suitable for producing large-diameter pipes using relatively narrow strip steel.High Strength and Pressure Resistance: The spiral seam distributes stress evenly.Cost-Effective: More economical than longitudinal welded pipes for large diameters.Good Welding Performance: Automatic double-sided SAW ensures stable welding quality.Custom Lengths Available: Pipes can be cut to specific lengths as required.3. Product SpecificationsItemSpecification RangeNominal DiameterDN200 - DN3000 (Φ219mm – Φ3000mm)Wall Thickness5mm – 30mm (customizable)Length6m – 18m (or customized)Steel GradeQ235B, Q345B, L245-L485 (API 5L), etc.Welding MethodDouble-sided Submerged Arc Welding (SAW)Surface TreatmentBlack, or anti-corrosion coatings (3PE, epoxy, etc.)4. Applicable StandardsStandard CodeStandard NameSY/T 5037Spiral Submerged Arc Welded Steel Pipe for Non-Pressure FluidsGB/T 9711Steel Pipe for Pipeline Transportation SystemsAPI 5LLine Pipe Specification (American Petroleum Institute)EN 10219Cold Formed Structural Hollow Sections (EU Standard)ISO 3183International Standard for Steel Line Pipes5. Main Applications✅ Pipeline Transmission:Long-distance transportation of oil and natural gasWater supply and drainage systemsDistrict heating pipelinesIndustrial fluid transmission (chemicals, pharmaceuticals, wastewater, etc.)✅ Structural Uses:Steel structures in buildings and bridgesPiling pipes for ports, piers, foundationsSupport pipes for tunnels and underground projects✅ Other Uses:Outer protection pipes for anti-corrosion and thermal insulation systemsSteel casing and sleeve pipes6. Common Anti-Corrosion Coatings3PE (Three-layer Polyethylene Coating): Ideal for underground or submerged pipelines.Epoxy Coal Tar Coating: Common in drainage, sewage, and municipal water supply systems.FBE (Fusion Bonded Epoxy): Excellent adhesion and corrosion resistance.Hot-dip Galvanizing: Suitable for environments with high oxidation requirements.