Hot-dip Galvanized Steel Pipe

📌 Product Description

Hot-dip galvanized steel pipe is a steel pipe that has been coated with a layer of zinc through the process of hot-dip galvanization. This process involves immersing the steel pipe into a bath of molten zinc at approximately 450°C, forming a metallurgical bond between the zinc coating and the steel substrate. The resulting zinc layer provides excellent corrosion resistance and extends the service life of the pipe in a wide range of environments.

Hot-dip galvanized pipes are available in both seamless and welded forms, and are widely used in applications where durability, corrosion resistance, and a clean, finished appearance are required.

⭐ Key Features

✅ Superior Corrosion Resistance

The zinc coating acts as a sacrificial layer that protects the base steel from rust and corrosion, even when the coating is scratched.

✅ Strong Mechanical Properties

Made from high-quality carbon steel, these pipes offer good tensile strength and load-bearing capacity.

✅ Durable Zinc Coating

The hot-dip process results in a uniform, tightly bonded zinc layer that adheres strongly to the surface and offers long-lasting protection.

✅ Cost-Effective Longevity

With minimal maintenance, hot-dip galvanized pipes offer a low life-cycle cost compared to painted or untreated steel pipes.

✅ Attractive Appearance

The silver-gray surface provides a clean, industrial aesthetic suitable for exposed use.

📐 Specifications

| Parameter | Description |

|---|---|

| Outer Diameter | 1/2" – 12" (DN15 – DN300), or customized |

| Wall Thickness | 1.5mm – 12mm |

| Length | 5.8m, 6m, 12m, or customized as required |

| Steel Grades | Q195, Q235, Q345, S235, S275, ASTM A53/A500, BS EN 10255, etc. |

| Zinc Coating | 200g/m² – 600g/m² (can be customized) |

| Pipe Ends | Plain, beveled, or threaded with plastic caps or couplings |

| Surface Finish | Hot-dip galvanized (shiny or matte), with or without oil coating |

| Manufacturing Types | Welded (ERW), Seamless |

| Tolerances | According to API, ASTM, or customer requirements |

📚 Standards Complied

| Standard | Description |

|---|---|

| ASTM A53 / A123 | American Standard for galvanized steel pipes |

| BS 1387 | British Standard for galvanized welded steel tubes |

| EN 10240 | European standard for zinc coating of steel tubes |

| ISO 65 | International standard for galvanized steel tubing |

| DIN 2444 | German standard for hot-dip galvanized steel pipes |

🏗️ Main Applications

Construction & Infrastructure

Structural supports, guardrails, scaffolding, greenhouse frames, roofing frameworks

Water Supply & Drainage Systems

Potable water pipelines, sewage lines, irrigation pipes

Gas & Air Transmission

Natural gas distribution, compressed air systems

Fire Protection Systems

Sprinkler pipe networks in residential, commercial, and industrial buildings

Fencing & Agricultural Use

Fencing posts, greenhouse poles, livestock shelters

Communication & Utility Structures

Electrical conduit, telecom towers, solar mounting frames

🛡️ Advantages Compared to Other Pipes

Longer lifespan (up to 50 years in dry environments)

Self-healing protection at scratches (zinc oxidation protection)

Suitable for both indoor and outdoor use

No painting required – maintenance-free in most applications

Excellent for welding, cutting, and threading

🎨 Surface Treatment Options

Hot-dip Galvanized (HDG): Immersed in molten zinc for full coverage protection

Pre-galvanized (PG): Zinc coating applied to steel strip before forming

Clear/Anti-rust Oil Coating: Applied to prevent white rust during storage

Passivation: Chromate treatment to enhance corrosion resistance and appearance

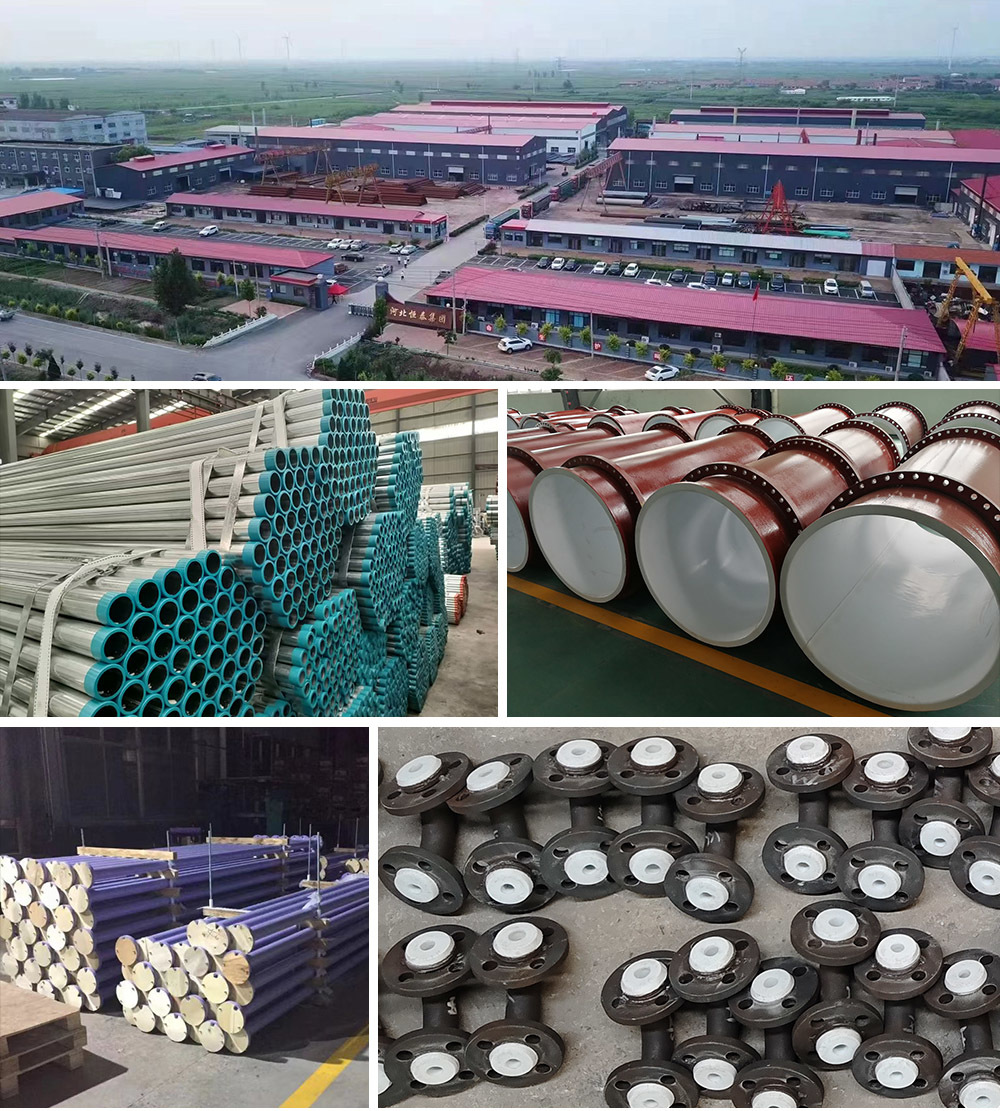

Factory Tour

Enterprise Qualification

Keywords

Hot-dip Galvanized Steel Pipe

Contact Us

Classification