Categories

Contact

E-mail :

mark@htzylinedpipes.com

WhatsApp:

+86-15632750373

Address:

Hebei Hengtai Group, 338 National Road North, Zhenggang Industrial Park, Yanshan County, Cangzhou City, Hebei Province

Ultra-high molecular weight polyethylene lining pipe

Steel-lined ultra-high molecular weight polyethylene tee/elbow.

Ultra-high molecular weight polyethylene (UHMWPE) wear-resistant pipe fittings include elbows, tees, and various special-shaped fittings. The company can manufacture custom fittings according to the specific requirements of enterprises. These pipe fittings are made from UHMWPE resin with a molecular weight of over 2 million, continuously extruded to form the fittings. They are suitable for medium transmission in special industrial enterprises such as mining, electricity, coal, and chemicals. The superior performance of these UHMWPE pipe fittings is primarily reflected in the following characteristics:High Wear Resistance: The wear resistance of UHMWPE is 4-7 times that of steel pipes, 3 times that of ordinary PE pipes, and 4 times that of nylon. Practical applications have proven that UHMWPE pipes are commonly used as wear-resistant pipes for transporting slurry with small particles.High Corrosion Resistance: UHMWPE has a saturated molecular structure, providing excellent chemical stability. It can resist corrosion from various corrosive media and organic solvents.High Flexibility: The elongation at break can reach over 400%. During construction, the pipe can undergo significant bending. Even when extended up to three times its original length during ground subsidence, it will not break.High Impact Resistance: UHMWPE has the highest impact strength among all plastics, 10 times that of high-density polyethylene and 6 times that of nylon. Whether subjected to strong external impacts or internal pressure fluctuations, it is difficult to crack.Low-Temperature Resistance: UHMWPE performs excellently at low temperatures. At -40°C, its impact strength remains high. It retains good performance even at extremely low temperatures, making it especially suitable for medium transmission in cold regions.Resistance to Scaling: The inner and outer surfaces of the pipes are smooth, with excellent non-stick properties and self-lubricating characteristics. Scaling substances are difficult to deposit and adhere, significantly reducing the cost of pipe descaling maintenance.Anti-Aging Properties: UHMWPE has superior anti-aging properties compared to PE100. When buried underground for 50 years, its mechanical properties only decrease by 20%.Energy-Saving Effect: The friction coefficient of UHMWPE is 0.07-0.11, and its roughness is only 1/6 of that of new steel pipes. The flow capacity exceeds that of steel pipes by more than 50%, and its inner diameter can be reduced by about 15% compared to steel pipes.Safety and Environmental Friendliness: UHMWPE is non-toxic and odorless, meeting national standards for drinking water pipeline use.Ease of Installation: The weight of UHMWPE pipes is only one-eighth that of steel pipes, greatly reducing installation costs. The pipe connection can be made by directly flaring the pipe body and flange docking, without the need for additional seals. It can also be connected by socketed electric fusion welding, offering high joint strength and easy operation.Technical Specifications:Product Name: Ultra-high Molecular Weight Polyethylene Wear-resistant Pipe FittingsTesting Standard: QB/T 2668.1-2017Test ItemStandardTest ResultConclusionTensile Strength≥25MPa30.8 MPaPassElongation at Break≥280%457.67%PassCharpy Impact Strength≥130 KJ/m²145.5 KJ/m²PassSand Abrasion Rate≤0.3%0.14%PassStatic Hydrostatic Test (100h)No cracking, no leakageNo cracking, no leakagePassApplications:Oil, natural gas, crude oil, and liquid transportationUnderground filling and tailings transportationPulp, chemicals, and food industry applicationsMining, metallurgy, and power industry pipelinesEnvironmental protection and wastewater treatment systemsThe ultra-high molecular weight polyethylene wear-resistant pipe fittings, with their superior wear resistance, corrosion resistance, high pressure resistance, and low-temperature performance, are ideal for use in harsh environments. They are widely used in industries such as mining, electricity, coal, and chemicals.

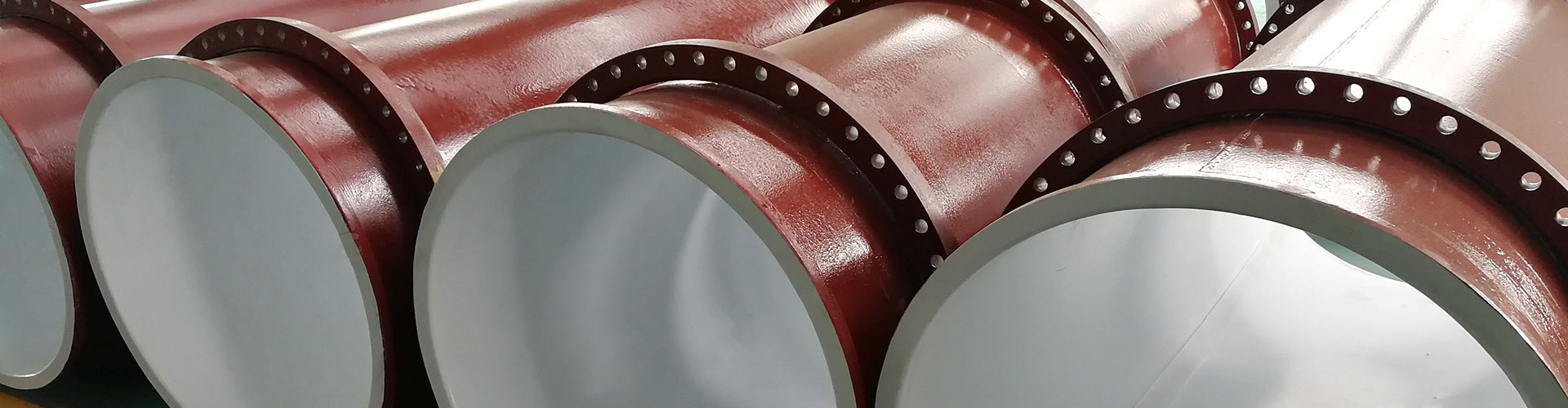

Ultra-high molecular weight polyethylene lining pipeline

Ultra-high molecular weight polyethylene steel composite pipe is a new type of pipe that combines wear resistance, corrosion resistance, non-scaling, and high-pressure resistance. It can meet the performance requirements of products in different environments and expands the application field of ultra-high molecular weight polyethylene pipes.

The steel-lined ultra-high molecular weight polyethylene (UHMWPE) storage tank

The steel-lined ultra-high molecular weight polyethylene (UHMWPE) storage tank combines the excellent properties of UHMWPE with the structural stability of traditional storage tanks. This storage tank is widely used in industries such as petrochemicals, fertilizers, pharmaceuticals, metallurgy, and environmental protection, for storing and transporting highly corrosive and aggressive media. It demonstrates exceptional reliability and durability, especially in harsh environments.Main Features:Excellent Corrosion Resistance: UHMWPE has a highly stable molecular structure, providing excellent resistance to a wide range of corrosive media such as acids, alkalis, salts, and oxidizing agents. Its corrosion resistance is far superior to traditional steel-lined storage tank materials.Extremely High Wear Resistance: UHMWPE is 4-7 times more wear-resistant than steel and far exceeds other plastic materials. It is especially suitable for storing liquids or slurry containing particles, significantly extending the service life of the storage tank.High Impact Resistance: UHMWPE has exceptional impact strength, 6 times that of nylon and 10 times that of high-density polyethylene. It can withstand external mechanical impacts or fluctuations in internal and external pressures without cracking.High Temperature Resistance: UHMWPE has good high-temperature resistance, maintaining stable performance in working environments between 60°C and 80°C, making it suitable for various storage requirements in different operating conditions.Self-lubrication: UHMWPE's self-lubricating properties reduce wear and adhesion during use, lowering maintenance costs and operational expenses.Anti-aging Properties: The anti-aging properties of UHMWPE are superior, allowing it to maintain performance for a long time. It significantly extends the service life of the storage tank, especially in outdoor or underground applications.Low Temperature Performance: UHMWPE maintains excellent mechanical properties even at low temperatures, withstanding temperatures as low as -40°C, making it suitable for storage applications in cold regions.Environmental and Safety Friendly: UHMWPE is non-toxic, odorless, and pollution-free, meeting national standards for food-grade and pharmaceutical-grade applications, ensuring safety and reliability.Reduced Scaling and Maintenance Costs: The inner and outer surfaces of the tank are smooth with excellent non-stick and self-cleaning properties, making it difficult for scaling substances to adhere. This greatly reduces the frequency and cost of tank cleaning and maintenance.Lightweight and Easy Installation: UHMWPE storage tanks are much lighter than traditional steel tanks, making them easier to handle, install, and transport, reducing installation costs.Technical Specifications:Tensile Strength: ≥25MPaElongation at Break: ≥280%Impact Strength: ≥130 KJ/m²Wear Resistance: 4-7 times that of steelCorrosion Resistance: Resistant to strong acids, alkalis, salts, and various organic solventsWorking Temperature: Stable in the range of -40°C to 80°CApplications:Petrochemical Industry: For storing corrosive media such as acids, alkalis, oils, and chemical solvents.Mining and Metallurgy: For storing tailings, acidic solutions, and chemicals.Food and Pharmaceutical Industries: For storing food-grade or pharmaceutical liquids, meeting safety standards.Environmental Protection: For storing wastewater, chemical waste, and in waste treatment processes.Other Corrosive Media Storage: Suitable for applications in fertilizer, power, and paper industries.The steel-lined ultra-high molecular weight polyethylene storage tank, with its excellent corrosion resistance, wear resistance, impact resistance, and high/low-temperature performance, is the ideal choice for many industries, providing a long-lasting, safe, and reliable storage solution.