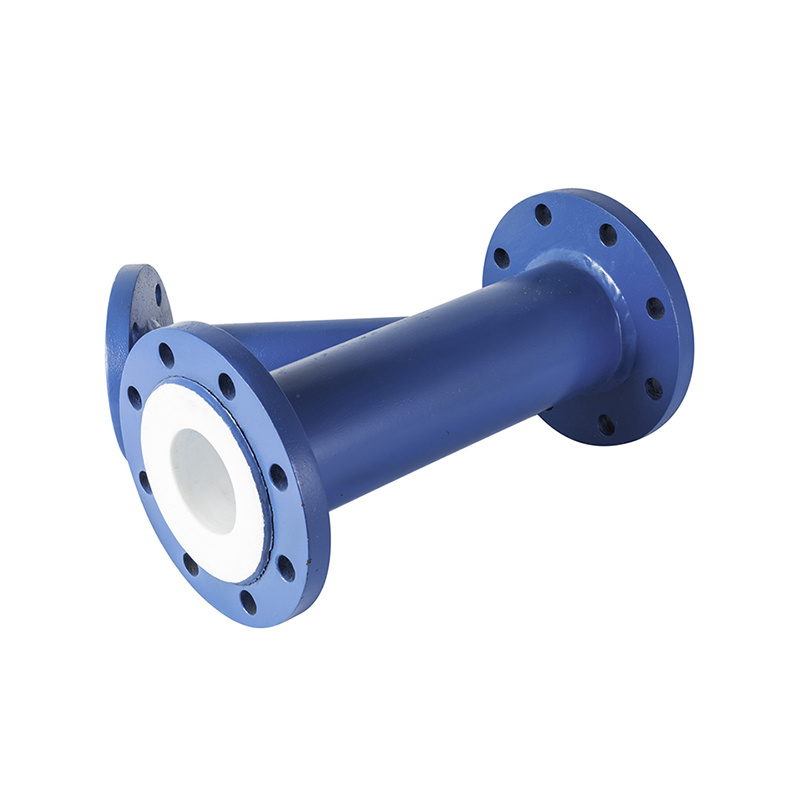

UHMWPE-lined steel pipes combine the high strength of steel with the superior wear and corrosion resistance of ultra-high molecular weight polyethylene (UHMWPE). These pipes are designed for transporting highly abrasive, corrosive, and high-impact materials, offering extended service life and reduced maintenance costs. The UHMWPE lining provides excellent self-lubricating properties, reducing friction and enhancing flow efficiency.

Key Features:

- Superior Wear Resistance: UHMWPE has outstanding abrasion resistance, significantly extending the lifespan of the pipeline.

- Corrosion Resistance: Resistant to strong acids, alkalis, and various chemicals, making it suitable for harsh industrial environments.

- Impact Resistance: The high molecular weight of UHMWPE ensures excellent impact absorption, preventing damage from high-velocity particles.

- Low Friction & High Flow Efficiency: The ultra-smooth surface reduces material adhesion and enhances flow capacity.

- Self-Lubricating Properties: Reduces the need for additional lubrication, decreasing maintenance requirements.

- Lightweight & Easy Installation: Lighter than traditional metal-lined pipes, facilitating easier handling and installation.

- Wide Temperature Range: Performs well under extreme temperatures, ensuring reliability in various industrial applications.

Standard Sizes:

UHMWPE-lined steel pipes are available in standard sizes, ensuring compatibility with various industrial applications:

- Nominal Diameter (DN): 50mm – 1200mm

- Wall Thickness: Customizable based on pressure and abrasion requirements

- Lining Thickness: Typically 3mm – 12mm, adjustable based on application needs

- Pipe Length: Standard lengths of 6m, 9m, or 12m, or as per customer requirements

- Pressure Rating: Up to PN25 (customizable for higher pressure applications)

- Flange Standards: Available in ANSI, DIN, JIS, GB, and other international standards

Applications:

- Mining Industry: Slurry transportation, tailings disposal, and mineral processing pipelines.

- Chemical Industry: Handling corrosive and abrasive chemicals, acids, and alkalis.

- Power Plants: Fly ash and coal slurry transportation pipelines.

- Water Treatment: Used for sewage, wastewater, and desalination plant pipelines.

- Dredging & Marine Engineering: Ideal for sand, mud, and gravel transportation.

Customization Options:

To meet specific project requirements, UHMWPE-lined steel pipes can be customized in the following ways:

- Pipe Diameter & Thickness: Adjustable to meet pressure, flow rate, and wear resistance needs.

- Lining Thickness & Material Grade: Customizable for enhanced durability in extreme conditions.

- Flange Types & Connections: Designed to fit ANSI, DIN, JIS, or other required standards.

- Length & Bending Options: Available in standard or custom lengths, including custom bends and fittings.

- Coating & External Protection: Additional anti-corrosion coatings or insulation for extended durability.

- Manufacturing Based on Technical Drawings: We offer fully tailored solutions based on customer-provided blueprints and specifications.

For further details or custom solutions, feel free to contact us!

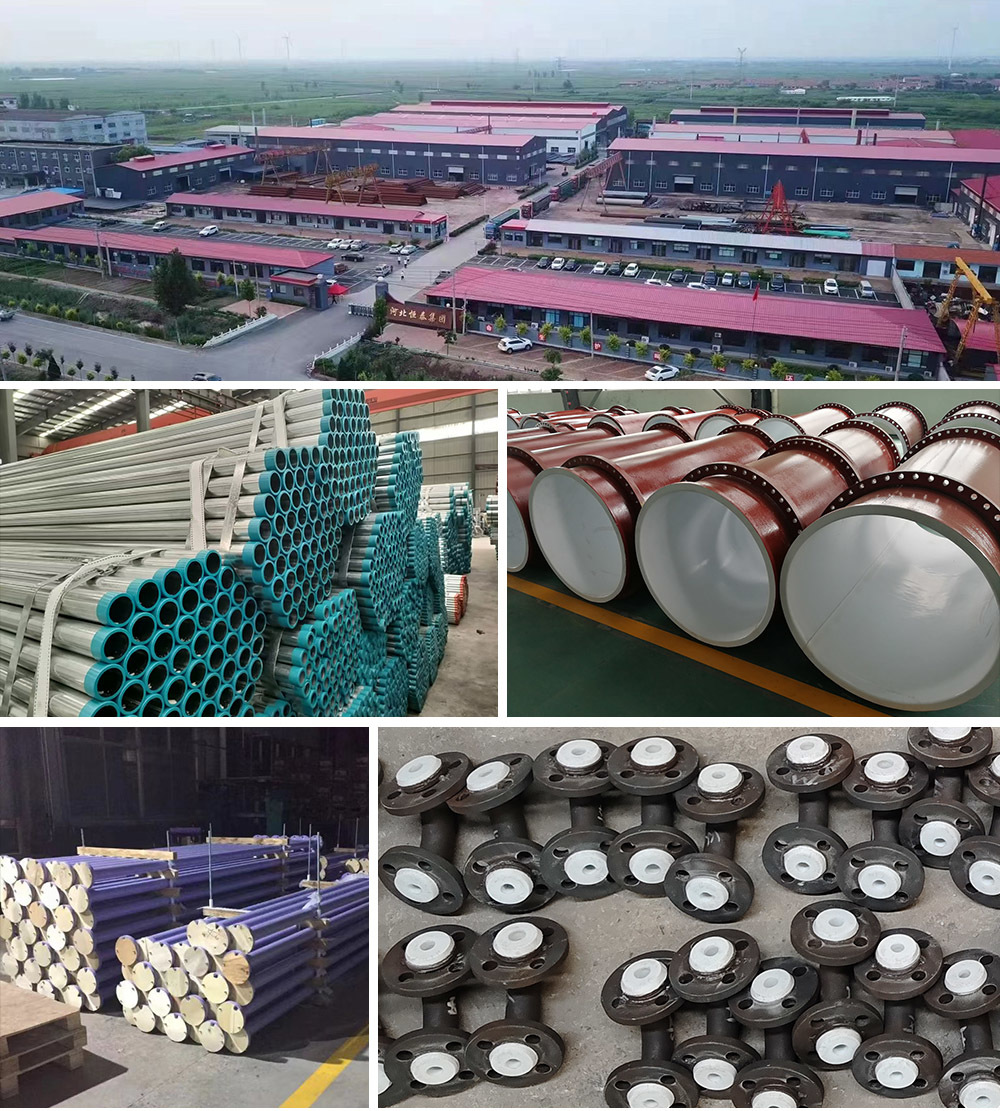

Factory Tour

Enterprise Qualification

Keywords

Ultra-high molecular weight polyethylene lining pipeline

Contact Us