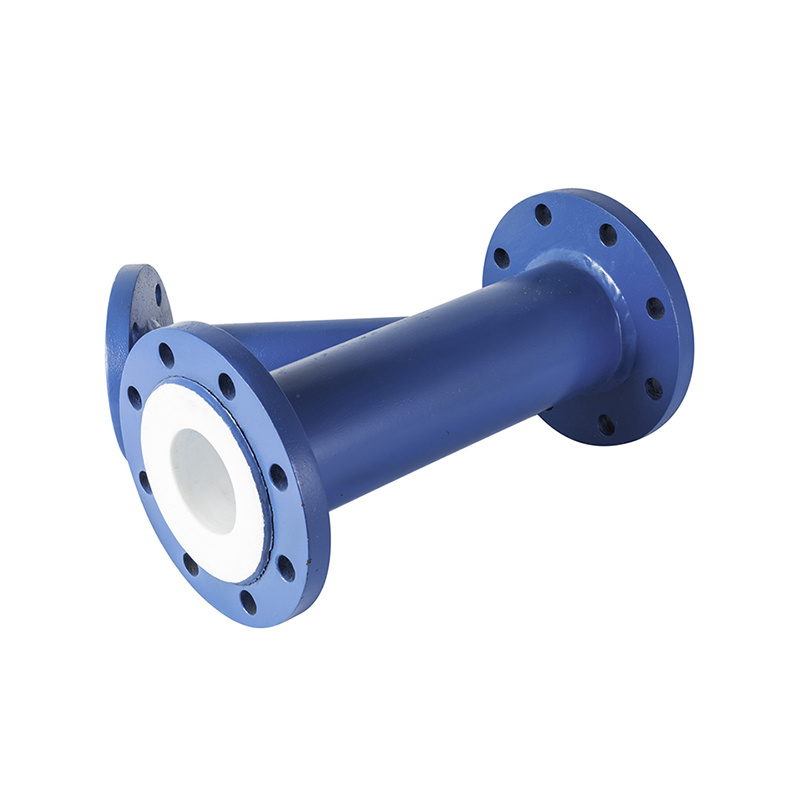

Tee pipe fittings are essential components in piping systems, used to split or combine flow in different directions. They have three openings: one inlet and two outlets (or vice versa), and are widely used in industries such as oil and gas, chemical processing, water treatment, power plants, and mining.

Types of Tee Pipe Fittings:

- Equal Tee: Both branch and main pipe have the same diameter, ensuring balanced flow distribution.

- Reducing Tee: The branch pipe has a smaller diameter than the main pipeline, used for flow control and size transitions.

- Barred Tee: Designed for pigging pipelines, commonly used in oil and gas industries.

- Lateral Tee (Y-Tee): A tee with a branch at a 45-degree angle, used in special flow systems.

Standard Sizes:

Tee fittings come in various standard dimensions to fit different piping systems:

- Nominal Diameter (DN): DN15 – DN1200 (1/2” – 48”)

- Wall Thickness: According to SCH10, SCH20, SCH40, SCH80, SCH160, or as per customer specifications.

- Pressure Ratings: Up to PN40 / Class 600 or higher as required.

- Branch Angles: Standard 90-degree, or customized angles such as 45-degree.

- Connection Types: Butt-weld, socket-weld, threaded, flanged, or grooved.

Materials Available:

- Carbon Steel: ASTM A234 WPB, WPC, etc.

- Stainless Steel: SS304, SS316, SS321, SS347, etc.

- Alloy Steel: ASTM A335 P11, P22, P91, etc.

- Lined Materials: Rubber-lined, UHMWPE-lined, ceramic-lined, or PTFE-lined for enhanced wear and corrosion resistance.

Applications:

- Oil & Gas Industry: Used in pipelines for crude oil, natural gas, and refined products.

- Chemical & Petrochemical Industry: For handling aggressive and corrosive fluids.

- Water Treatment & Desalination Plants: For seawater, wastewater, and treated water transport.

- Power Plants: Used in steam, cooling water, and ash handling systems.

- Mining & Slurry Pipelines: For transporting abrasive slurry, tailings, and mineral concentrates.

Customization Options:

To meet specific project and industry needs, tee pipe fittings can be fully customized in:

- Size & Thickness: Custom diameters, wall thickness, and branch configurations.

- Lining Materials: Rubber, UHMWPE, ceramic, or PTFE lining for enhanced durability.

- Flange Standards: ANSI, DIN, JIS, GB, or customized connection flanges.

- Surface Treatment: Galvanization, epoxy coating, or anti-corrosion paint.

- Special Angles & Configurations: Custom branch angles other than 90° and special designs based on flow requirements.

- Manufacturing Based on Drawings: Fully tailored tee fittings according to client specifications and technical blueprints.

For further details or customized solutions, feel free to contact us!

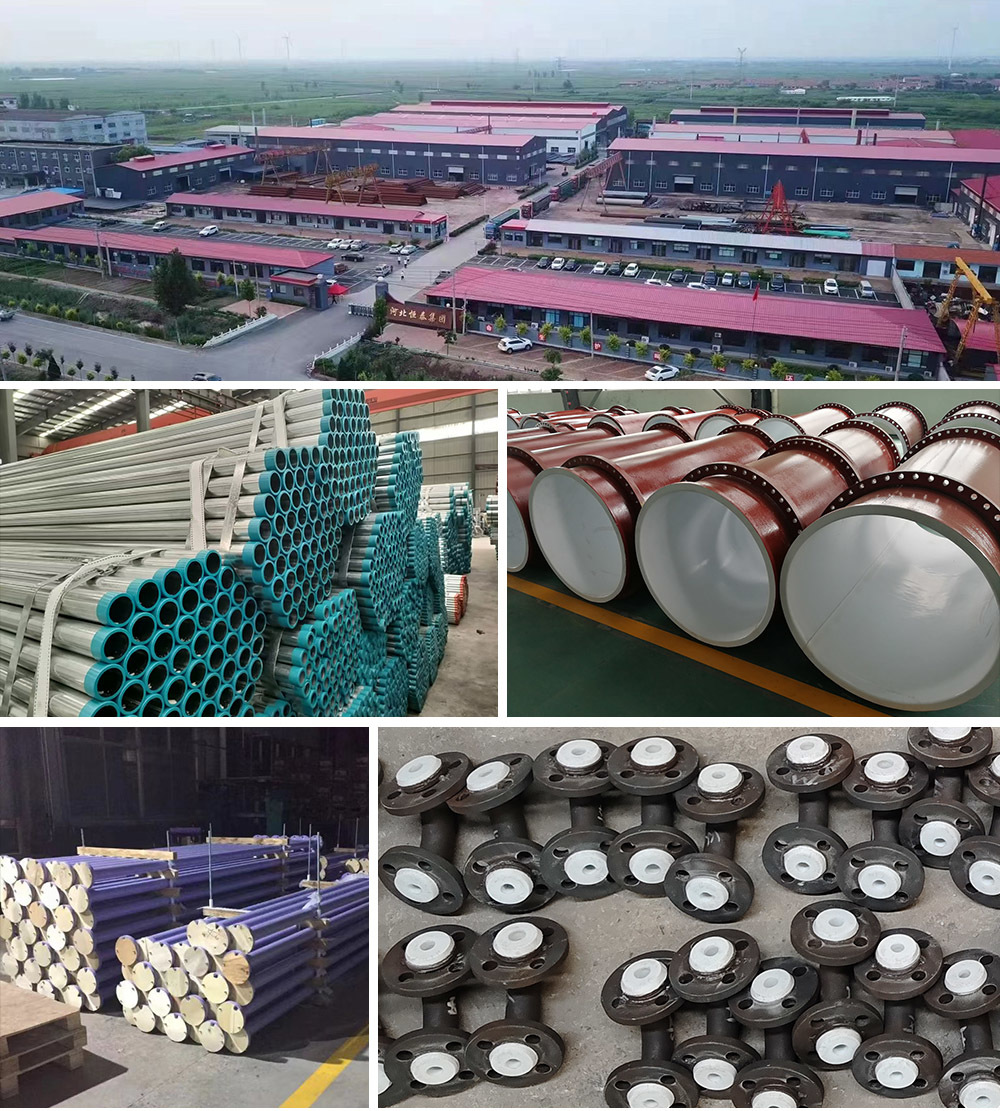

Factory Tour

Enterprise Qualification

Keywords

Tee Pipe Fittings

Tee pipe fittings are essential components in piping systems, used to split or combine flow in different directions. They have three openings: one inlet and two outlets (or vice versa), and are widely used in industries such as oil and gas, chemical processing, water treatment, power plants, and mining.

Contact Us

Classification