Product Introduction

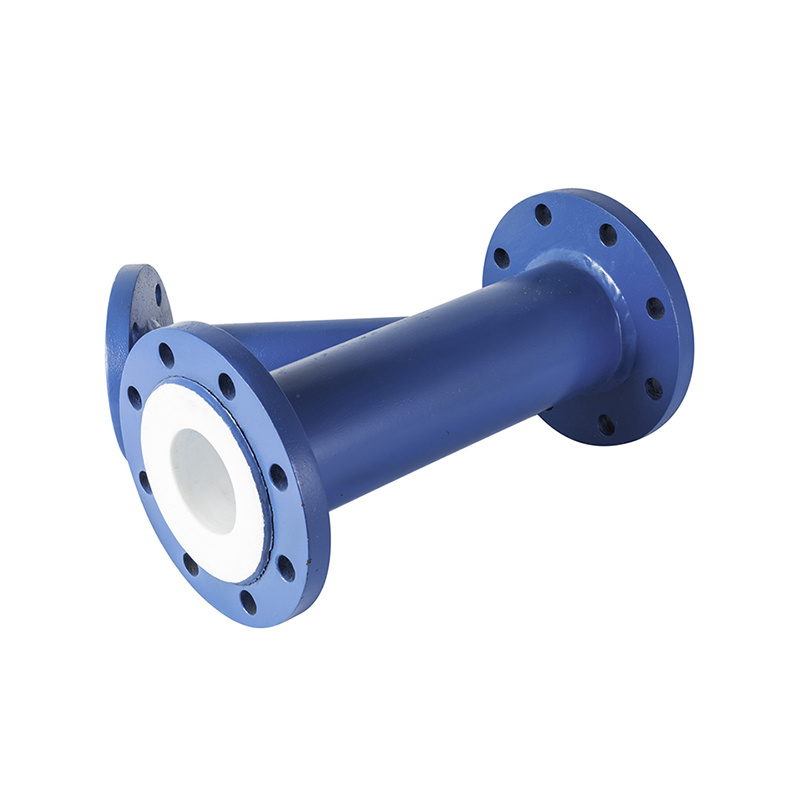

Choosing the right anti-corrosion materials is the best way to control corrosion. To solve the problem of hydrochloric acid corrosion, steel-lined glass products can be selected.

Steel-lined glass is made by lining the inner wall of preheated steel pipe fittings with molten borosilicate glass using a special method, ensuring that the glass is firmly adhered to the inner wall and is in a state of compression, forming a composite of steel and glass - steel-lined glass fittings. Steel-lined glass fittings can also be combined to create heat exchangers and other products.

Steel-lined glass products have high chemical stability, smooth inner walls that do not clog, low fluid resistance, and are wear-resistant, corrosion-resistant, high-temperature resistant, pressure-resistant, and vacuum-resistant. In industrial production, the unique properties of glass are fully utilized, not only replacing rare metals such as stainless steel, titanium, and aluminum, but also steel-plastic lined pipes, which significantly stabilize production processes, reduce maintenance time and costs, and improve product quality and economic benefits.

Product Specifications

Sleeve Specifications:

| Nominal Diameter DN | Length L |

| 25 | 1000 |

| 32 | 1000 |

| 40 | 1000 |

| 50 | 2000 |

| 65 | 2000 |

| 80 | 2000 |

| 100 | 2000 |

| 125 | 2000 |

| 150 | 2000 |

| 175 | 2000 |

| 200 | 2000 |

| 225 | 1500 |

| 250 | 1500 |

| 300 | 1000 |

| 350 | 1000 |

Characteristics and Usage Range of Steel-Lined Glass Fittings

1. Performance and Technical Parameters

Nominal Pressure:PN≤2.0MPa Operating Temperature -20℃ to 320℃

Cold Shock: ≤120℃ Thermal Shock ≤180℃

Temperature Resistance to Sudden Changes 230℃

Operating Medium:Acids and various organic and inorganic chemicals (except hydrofluoric acid, fluorides, and hot concentrated phosphoric acid). PH value >12 strong alkaline media are not suitable.

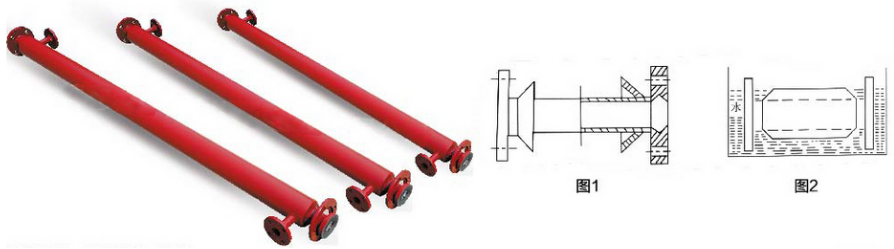

2. Installation and Usage Precautions

1. There is no need to worry about strength during installation, but excessive concentrated loads and impacts on steel-lined glass products, improper clamping and unloading, and misalignment of flange sealing surfaces can cause damage to the inner glass lining. The sealing gaskets between flanges can be selected from rubber gaskets, asbestos board gaskets, graphite-asbestos gaskets, PTFE gaskets, soft lead, or other semi-rigid materials based on the medium and process. The thickness should not be less than 4mm, and the outer diameter should be greater than the flange rim.

2. If the gap between flanges is large, the thickness of the gasket can be increased to compensate. Avoid hard tightening of bolts that could damage the sealing surface; bolts should be tightened evenly in a diagonal pattern.

3. Welding, cutting, or localized heating with flames on steel-lined glass pipes is prohibited to prevent glass from shattering. Pressurization and temperature increase or decrease should be done slowly and must not exceed the specified range.

4. During installation, ensure the gasket is properly positioned, and when connecting bolts, apply force evenly to prevent excessive pressure on the upper side, which could damage the flange glass sealing surface. After installation and pressure testing, use compressed air or water to blow out any debris and residual substances.

Borosilicate Glass Parameters

| Medium | Concentration (%) | Temperature (℃) | Time (hours) | Glass Weight Loss (mg/cm2) | Enamel Weight Loss (mg/cm2) under the same conditions |

| Sulfuric Acid | 10 | - | 4 | 0.0085 | 0.17 |

| Hydrochloric Acid | 15 | - | 4 | 0.0077 | 0.165 |

| Nitric Acid | 15 | - | 4 | 0.00525 | - |

| Sodium Hydroxide | 5 | 50 | 4 | 0.0295 | - |

Note: Glass has poor alkali resistance; it is advisable to use it for low-temperature dilute alkaline solutions when necessary.

Thermal Stability and Usage Range The thermal stability of glass is relatively poor, but when lined inside red fiber steel pipes, the cooling contraction of the steel pipe puts the glass in a state of stress, which, aided by compressive stress, enhances the thermal stability of the glass. Sprayed glass has high thermal stability due to the effect of the base glaze, which tightly bonds the glass and iron body together.

Characteristics and Usage Range of Steel-Lined Glass Fittings

| Types | Blown Lined Glass Pipe | Expanded Lined Glass Pipe | Sprayed Glass Pipe |

| Applicable Temperature (℃) | 0-350 | 0-280 | 0-280 |

| Temperature Resistance to Sudden Changes: Cold Shock (℃) | 120 | 200 | 200 |

| Temperature Resistance to Sudden Changes: Thermal Shock (℃) | 180 | 250 | 250 |

Note: 1. Cold shock refers to sudden cooling from heat; thermal shock refers to sudden heating from cold.

2. The glass used for lining is borosilicate glass (95 material).

Pressure Resistance The pressure resistance of the lined glass pipe is unrelated to the glass used, but only related to the structure. As long as the welds and pipe walls are intact, the glass lining will not shatter. The pressure has been used up to 2.0MPa. Generally, the operating pressure is ≤1.6MPa.

Mechanical Strength Glass is brittle and has low mechanical strength. However, the glass lining is protected by the steel pipe from external impacts, and generally, it will not shatter or fall off from minor impacts. If the pipe wall is dented, the glass lining may fall off. Sprayed glass has a strong bond, and generally, it will not fall off from minor impacts.

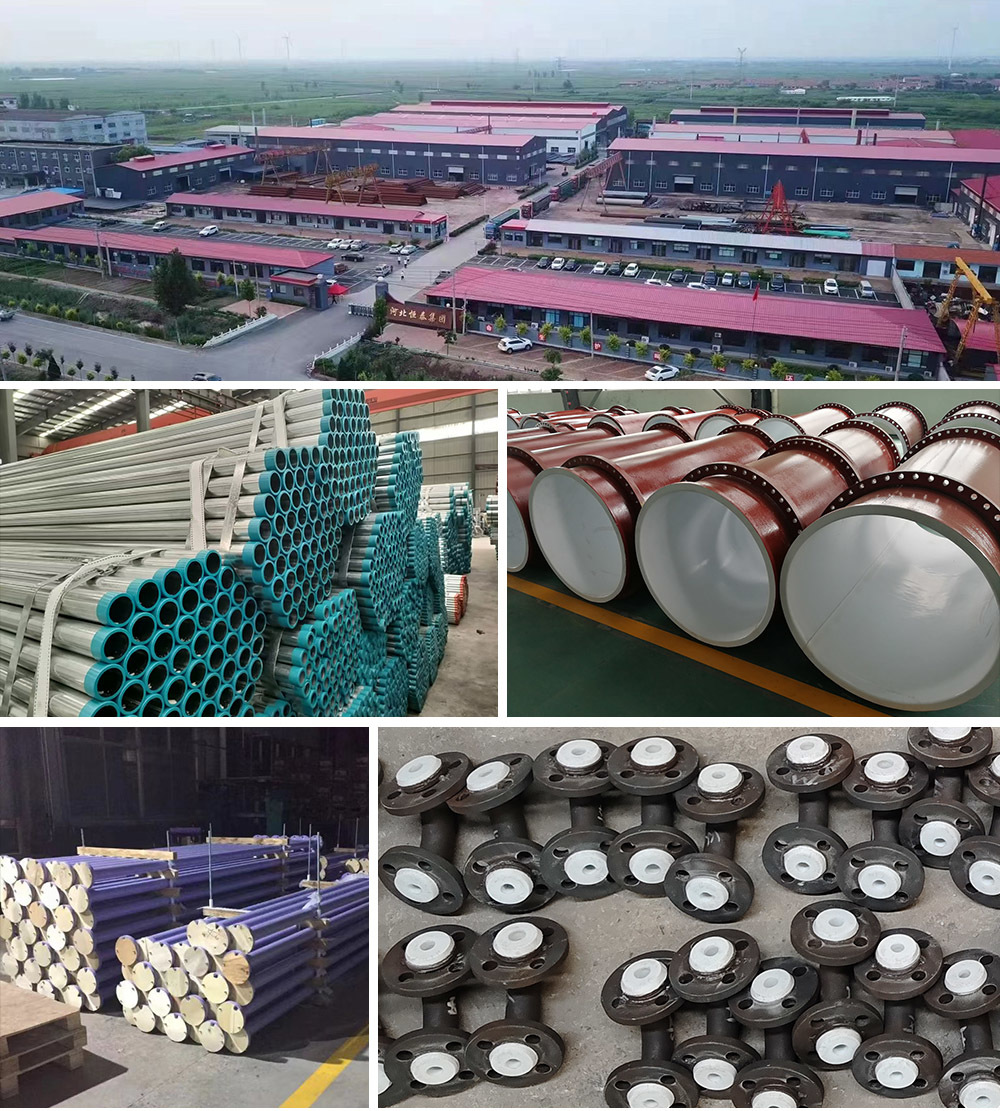

Factory Tour

Enterprise Qualification

Keywords

Lined glass pipe fittings

Contact Us

Classification