Categories

Contact

E-mail :

mark@htzylinedpipes.com

WhatsApp:

+86-15632750373

Address:

Hebei Hengtai Group, 338 National Road North, Zhenggang Industrial Park, Yanshan County, Cangzhou City, Hebei Province

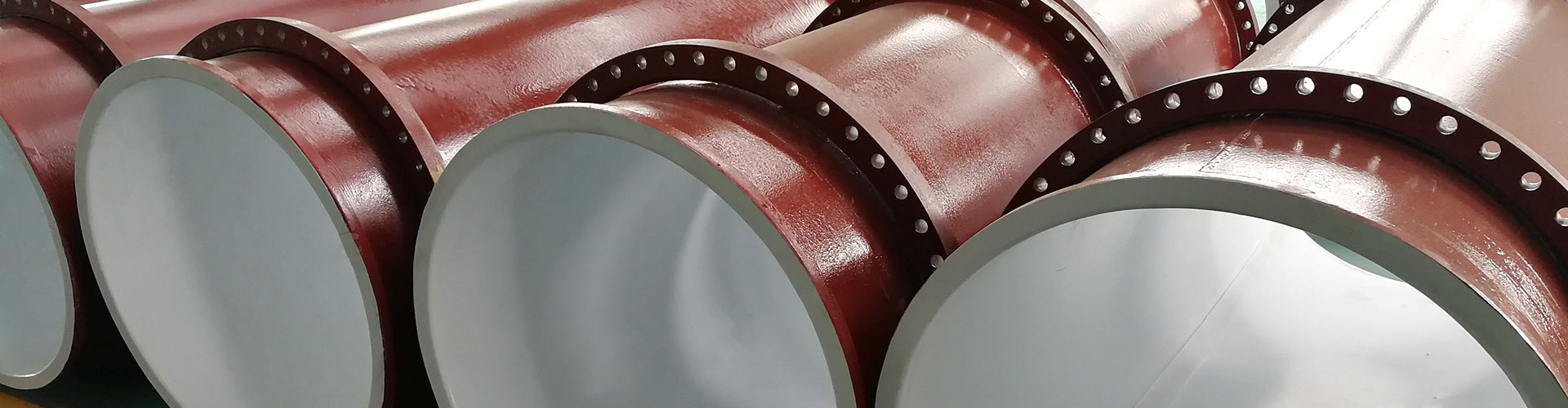

Internally and Externally Coated Pipes

Inner and outer coating composite pipes

Inner and outer coating composite pipes (also known as epoxy coated or plastic-coated composite pipes) combine the strength of steel pipes with the excellent corrosion resistance of plastic coatings. These pipes are widely used in various industries, including petroleum, chemical, water supply, heating, and other infrastructure systems, where resistance to harsh environments is crucial. The composite pipe consists of a steel pipe as the core and plastic coatings on both the inner and outer surfaces to provide superior protection.Key Features:Superior Corrosion Resistance: The inner and outer plastic coatings provide excellent protection against rust, corrosion, and chemical attack. The plastic coatings are typically made of epoxy, polyethylene, or polypropylene, which ensure resistance to a wide range of corrosive substances such as acids, alkalis, salts, and other chemicals.Enhanced Durability: The combination of steel and plastic coatings extends the service life of the pipe. The steel pipe offers strength and pressure resistance, while the plastic coatings protect against environmental factors such as water, air, and chemicals, significantly reducing maintenance costs and downtime.High Pressure Resistance: The steel core provides excellent pressure resistance, making the composite pipe suitable for high-pressure applications, including water and gas transportation, as well as industrial processes that require robust and reliable piping systems.Smooth Inner Surface: The inner coating provides a smooth surface that reduces friction and minimizes flow resistance. This helps improve the efficiency of fluid or gas transport and reduces energy consumption in the system.Temperature Resistance: The composite pipe is designed to withstand both high and low temperatures, depending on the type of plastic coating used. For example, epoxy coatings can withstand temperatures up to 80°C, while polyethylene can handle temperatures up to 60°C.Anti-Scaling and Anti-Fouling: The smooth inner coating reduces the accumulation of scale and debris, improving the flow characteristics and reducing the need for maintenance. This is particularly useful in water and wastewater transport applications.Improved Aesthetic Appearance: The outer plastic coating can be customized with various colors and finishes, making it suitable for both above-ground and underground installations, while offering an aesthetically pleasing look.Lightweight and Easy to Install: The plastic coating reduces the overall weight of the pipe, making it easier to transport, handle, and install. The pipes are often easier to manage compared to solid metal pipes, reducing installation time and costs.Applications:Water Supply and Drainage: For transporting potable water, wastewater, and sewage, where corrosion resistance and hygiene are important.Oil and Gas Transport: For pipelines that need to withstand harsh environments and corrosion from hydrocarbons and other chemicals.Industrial Process Piping: Suitable for chemical plants, pharmaceutical plants, and manufacturing facilities that require durable, corrosion-resistant piping.Heating Systems: For use in district heating or industrial heating systems, where resistance to chemicals and high temperatures is essential.Marine and Coastal Areas: Especially useful in coastal areas or other environments where pipes are exposed to saltwater and other corrosive elements.Technical Specifications:Outer Coating Material: Typically epoxy, polyethylene, polypropylene, or PVC.Inner Coating Material: Epoxy, polyurethane, or other corrosion-resistant materials.Pressure Rating: Designed to handle pressures up to 16MPa or higher, depending on the pipe size and application.Temperature Range: Varies based on the coating material but typically ranges from -20°C to 80°C.Standard: Complies with international standards such as ISO, ASTM, or equivalent, depending on regional regulations.Benefits:Extended Service Life: Protects against corrosion and wear, significantly extending the life of the pipe.Cost-Effective: Reduces the need for frequent maintenance or pipe replacement.Environmental Protection: Provides a more sustainable solution for transporting hazardous or corrosive materials.Reliable Performance: The combination of steel and plastic coatings ensures reliable performance in various challenging environments.Inner and outer coated composite pipes offer an advanced solution for industries requiring durable, corrosion-resistant, and high-performance piping systems, ensuring long-term reliability and cost savings in maintenance.